Explosive new development in small-scale mining

There is currently no reliable solution to reduce the environmental impact of small-scale mines, especially considering that current mining technology relies on rock blasting and mobile mining equipment for loading and transportation. Some of this equipment uses the expensive and difficult to install Measurement While Drilling (MWD) system, which is inefficient for small scale mining operations. The EU-funded SLIM project set out to develop cost-effective and more sustainable ways to blast and fragment rock using explosives in small-scale mining operations. Using advanced automatic blast design software, the SLIM project consortium focused on mitigating typical mining issues such as airborne particulate matter, vibrations and nitrate leaching. “The SLIM approach consists of injecting state of the art techniques into the mining operation by developing tools to control the excavation face, fine-tune the processing plant and reduce environmental effects, in order to improve feasibility, and profitability of mines, and gain public acceptance and trust,” says project coordinator José Sanchidrián.

A new generation of explosives

The SLIM team started by developing technologies capable of characterising explosives, identifying blasted rock fragments using artificial intelligence, and using systems that can predict the effect of certain explosives on specific rock types. SLIM developed a new generation of explosives and smart blast design software that can characterise rocks better than current systems and reduce the impact of rock blasting on the environment. This development is not only important for the European mining industry but for mining operations all over the world, to help them reduce economical costs and environmental impact such as groundwater contamination. The team experimented with, and developed, models to simulate how explosives would perform in mining operations, such as understanding rock fragmentation, the velocities, and the damage caused. Such information has already given mining operations the data they need to better understand and improve their overall performance by being as efficient as possible with minimal environmental impacts.

MWD using LiDAR

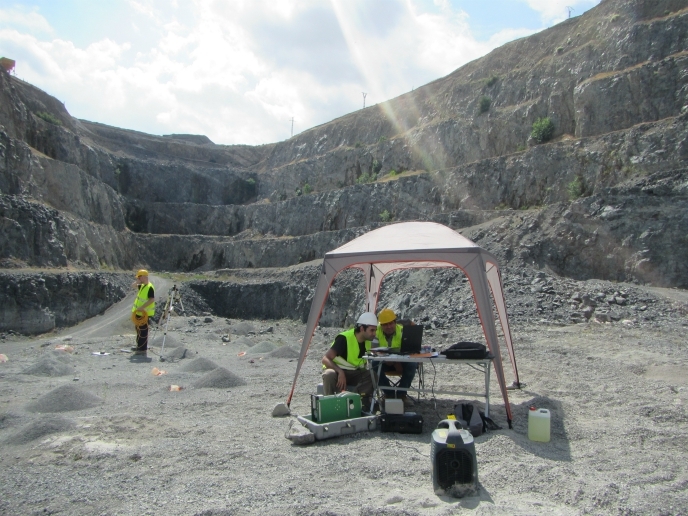

SLIM developed and retrofitted a more cost-efficient Measuring While Drilling (MWD) system that uses the detailed analysis of photographs to predict the impact of explosives on target rock. In an effort to make mine planning smoother, the SLIM team created a system that uses light detection and ranging (LiDAR) to analyse rock damage and environmental impact after a blast, as opposed to the non-direct methods used currently. The SLIM team also developed a software that mitigates negative impacts such as fly rock or vibrations, and characterises the result of a blast, or the ‘muck hole’. “This software is important to improve the surface blasting work, as only reliable and correct assessments of blasting results improve mining operations,” Sanchidrián says.

Real world data for further development

Minera de Órgiva, a SLIM partner from Spain, used improved rock excavation technologies, and processing plant monitoring and control to nearly double its production at Sierra de Lújar mine. This enabled the profitable mining and processing of lower yielding ore – from a cutoff grade of nearly 40 % fluorite to an expected cutoff of 20 % by the end of the project. The result is more than a threefold increase in reserves and extending the working life of the mine by at least 50 years. “The SLIM project partners have accumulated an exceptional amount of data from laboratory and field trials and this dataset has a fundamental value in facilitating future research and development in the fields of explosives technology, rock blasting, performance assessment, and mining automation,” Sanchidrián concludes.

Keywords

SLIM, small-scale mining, mineral resources, Measuring While Drilling, smart explosives