Uncovering the potential of nanotextured surfaces

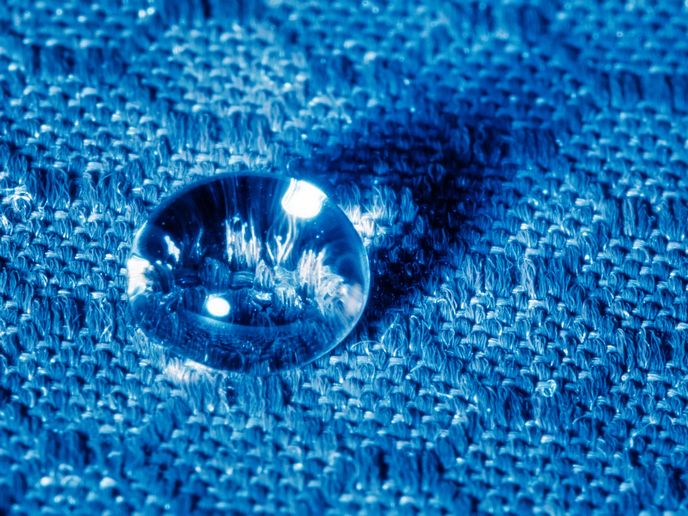

It is well known that flexible materials can absorb mechanical energy and resist mechanical damage. However, realising flexibility in coatings and films while maintaining liquid repellence remains a scientific and technological challenge – a challenge that the EU-funded NICEDROPS project decided to take up. “Our goal was to develop high-precision, nanotextured surfaces with controlled nanomechanical properties,” says Manish K. Tiwari, Royal Society Wolfson fellow and professor of Nanoengineering at University College London. “We then wanted to use these surfaces to study how nanoengineering can delay ice formation, resist high-speed liquid impacts and protect against abrasion and corrosion.”

The benefits of flexibility

One of the first findings to come out of the project was that electrochemical anodisation can be used to achieve morphology control at the nanoscale. What’s more, this can be done using environmentally friendly electrolytes and etchants. Furthermore, by rationally assimilating organic components into self-replicating liquid repellent coatings, the project was able to highlight the benefits of flexibility. “We showed that by using flexible materials, we can improve the robustness of repellent surfaces,” explains Tiwari. “This is a principle that natural examples of liquid repellent surfaces such as butterfly wings and plant leaves inherently benefit from.” Not only was this discovery published in ‘Nature Materials’, researchers have already used it to make robust coatings with a wide variety of materials.

Metal-organic frameworks

The project, which received support from the European Research Council, also focused on metal-organic frameworks (MOFs). According to Tiwari, surface-grown MOFs can be used as sustainable, transparent and amphiphobic coatings. “These MOFs allow us to avoid using poly- and polyfluoroalkyl substances (PFAS), which are known to have major health and environmental issues,” he says. Researchers also demonstrated how these surfaces can resist high-speed liquid impact and offer low ice adhesion, not to mention the potential to absorb pollutants directly from the air. “We feel these nano-precision, PFAS-free surfaces should have a fairly wide range of applications,” adds Tiwari.

Exploring the field of self-powered sensors

Another key outcome was the development of a nanocomposite material that is simultaneously piezoelectric and piezocatalytic without the need for any poling. “These self-poled films introduced us to the field of self-powered sensors, which we see as an exciting new area of research for our team,” remarks Tiwari. Researchers have already teamed up with a clinician to develop sensor-based surgical gloves that could enable safer surgeries.

New insights, more work

The work done during the NICEDROPS project has uncovered the potential of nanotextured surfaces. “I hope the scientific community and society benefit from our insights on using mechanical flexibility for better and more robust surfaces, along with our ideas on PFAS-free nano-coatings,” concludes Tiwari. “Most of all, I hope that people consider these ideas when thinking about coatings that need to survive in harsh environments and withstand high-speed impacts.” Researchers are currently investigating the feasibility of launching a spin-off company to commercialise PFAS-free nano-coatings.

Keywords

NICEDROPS, coatings, nanotextured surfaces, nanoengineered, flexible materials, liquid repellence, metal-organic frameworks, nanocomposite material