Electricity from industrial waste heat

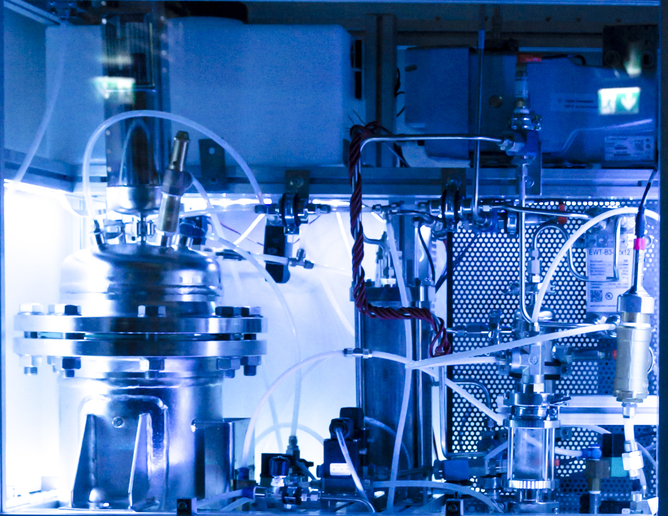

The organic Rankine cycle (ORC) technology — which recovers surplus low-grade heat — has major potential to help fulfil EU 20-20-20 targets. However, existing technology does not address small temperature differences compared to the ambient air. The 'Low temperature heat valorisation towards electricity production' (LOVE)(opens in new window) project sought to identify low-temperature (less than 120 degrees Celsius) waste heat sources and develop cost-effective technologies for converting them into electricity. Project partners defined a methodology for optimal integration of thermodynamic cycles that was based on pinch analysis and process integration. This was mainly applied to the test cases identified in the cement sector. Two 100 kWel ORC prototypes were integrated into 2 pilot study cement plants for waste heat recovery and power generation. Components that include a radial inflow turbine, finned tube heat and packed column heat exchanger were designed and sized for these pilot studies. Theoretical studies for a 1 MWe ORC system were also conducted. Different prototypes of polymeric gas–liquid heat exchangers were manufactured and tested under laboratory conditions. Capillary-tube heat exchangers were easily produced with promising results concerning heat transfer and pressure drop. Designs based on a polymeric film showed very good heat transfer performance but challenging manufacturing. The potential to extract waste heat from solid material was also studied by using the cement cooler as a test case. Modelling and simulation of heat and mass transfer phenomena allowed identifying possible modifications for the cement cooler design to enhance heat recovery. Based on the prototypes, project partners performed a detailed techno-economic assessment for low-temperature waste heat recovery. Results indicated payback times higher than those generally accepted by industry for off-production investments. Safety and environmental hazards of ORC installations were also evaluated, including a full life-cycle assessment analysis regarding the carbon dioxide footprint. Project dissemination activities included publications in journals, presentations and conferences. A patent application was also filed for waste heat recovery from rawmill flue gasses.