Conductive fabric harvests body heat to drive wearable computers

Imagine ditching your fitness tracker for a sweatshirt that could monitor your heart rate and record the intensity of your workout. The problem, of course, is that gym clothes need to be washed after use, and electronics famously don’t mix well with water. The EU-funded ThermoTex project addressed that challenge by investigating the potential for plastic-based, wearable electronics that can operate without batteries, instead harvesting energy from the wearer’s body heat.

Space probes

Thermoelectric generators exploit the temperature difference across a surface to produce electricity, sometimes using radioactive material as a heat source. “They are typically used where money doesn’t matter,” says Christian Müller, ThermoTex project coordinator. “Thermoelectric devices have been used to power space probes, as well as lighthouses in the Arctic.” Existing thermoelectric technologies rely on delicate and toxic metal alloys that are unsuitable for use in textiles. To create wearable electronics, Müller and his team at Chalmers University of Technology in Sweden worked with conductive plastics. “These are less efficient than metal alloys, but are super cheap to process and manufacture, so we gained a lot on the cost side of things,” he explains.

Temperature gradient

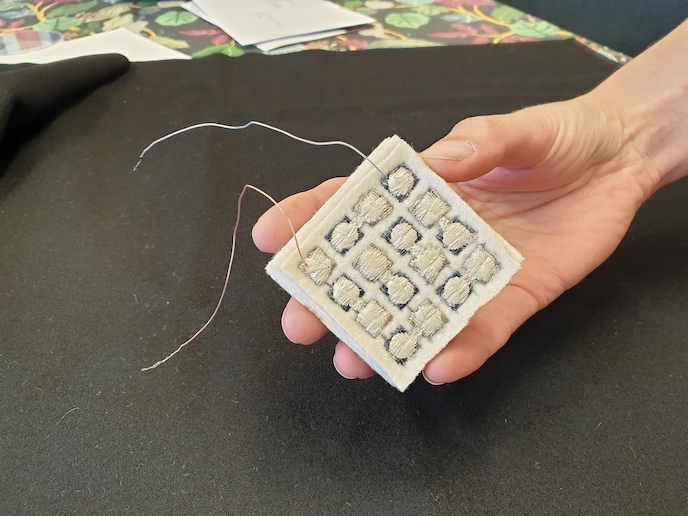

However, the efficiency of thermoelectric devices depends on how big that difference in temperature is. “We’re not talking huge amounts of power you can harvest in the end,” adds Müller. “We’re interested in developing this technology to power small wearable devices and Internet of Things sensors.” To do this, the team turned conductive plastics into fibres or yarns and ultimately textiles which could be organised like an electronic circuit. Their proof of concept can only generate around a microwatt of power – much less than is offered by the photovoltaic cell in a solar-powered calculator. Yet as Müller explains, this can still be useful: “I envision a selective sensor, not a continual sensor, that collects energy in a capacitor and sends data intermittently.” Müller’s thermoelectric yarns can be washed at least 15 times, far more than commercially available silver-plated yarn. Even silver-based yarns can be made washable, as a visiting researcher, Byungil Hwang from Chung-Ang University in South Korea, demonstrated. This sort of collaboration, says Müller, is where the value of the EU funding is most apparent.

Accelerating the field

“The grant gave so much more than just paying for things,” he notes. “Funding from the European Research Council gave us a big approval stamp, so other groups wanted to work with us, and were inspired to do their own research too.” This activity, Müller says, has helped to accelerate the field of wearable thermoelectrics over the past 5 years: “A lot of other groups picked up on the idea. It’s important that it’s not just us working in a vacuum, but a whole field.” As a result of the ThermoTex project, the team has filed 29 papers with 10 others in the pipeline. Together with the team of Mariano Campoy-Quiles from ICMAB-CSIC in Spain, they were also awarded a patent for a novel material that can switch between the type of majority carrier when illuminated with UV light. This, Müller says, is the ultimate highlight of research: people, papers and patents.

Keywords

ThermoTex, thermoelectric, fabric, yarn, plastic, silver, lighthouse, capacitor, sensor, Internet of Things