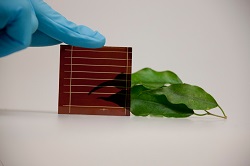

Perovskite-silicon solar cell combination helps researchers achieve high efficiency in photovoltaic power generation

Photovoltaic systems, which harvest sustainable and clean energy from the sun, continue expanding faster than any other renewable energy source thanks to ever-reducing costs. In that regard, silicon-based solar cells dominate the market due to their high efficiency and stability at low processing costs. But other devices, based on the emerging perovskite technology, have also entered the spotlight. This technology appears especially promising as it may be used to boost the efficiency of silicon cells further. A team of researchers partially supported by the EU-funded CHEOPS project have combined silicon and perovskite-based cells in a ‘tandem’ formation to deliver more power than either cell could manage alone. Their solar cell achieved an efficiency of 25.2 %. The findings of the study were published in the ‘Nature Materials’(opens in new window) journal. This research demonstrates a tailored perovskite deposition process that is fully compatible with existing industrial monocrystalline silicon bottom cells and has the potential to achieve “power conversion efficiencies above 30 % at reasonable costs.” Quoted in a news article published on the project website(opens in new window), co-author Quentin Jeangros explains: “Silicon’s surface consists of a series of pyramids measuring around 5 microns, which trap light and prevent it from being reflected. However, this surface texture makes it hard to deposit a thin homogeneous film of perovskite.” When the perovskite is deposited in liquid form, as it usually is, it accumulates in the valleys between the pyramids while leaving the peaks uncovered. This leads to short circuits. Scientists at the École Polytechnique Fédérale de Lausanne and Centre Suisse d’Electronique et de Microtechnique addressed this issue by using evaporation methods to form an inorganic base layer that fully covers the pyramids before depositing the organic components of the perovskite from a solution. A low temperature annealing step then crystallises the perovskite absorber. The tandem solar cells benefit from the texture of the silicon as it enables a record photocurrent and hence a high performance. Florent Sahli, the first author of the study, adds: “Until now, the standard approach for making a perovskite/silicon tandem cell was to level off the pyramids of the silicon cell, which decreased its optical properties and therefore its performance, before depositing the perovskite cell on top of it. It also added steps to the manufacturing process.” Integration into existing solar energy production lines The processes developed in this research have been designed to add only a few specific stages to the silicon bottom cell fabrication. So silicon cell manufacturers won’t be adopting a whole new solar technology when implementing a perovskite top cell. Despite the team’s breakthrough, more work needs to be done before this technology can be adopted commercially, especially with respect to long-term stability. The ongoing CHEOPS (Production technology to achieve low Cost and Highly Efficient phOtovoltaic Perovskite Solar cells) project aims to bring photoactive perovskite materials, synthetic compounds that share the crystal structure with the naturally occurring mineral perovskite named after the Russian mineralogist Lev Perovski, closer to the market. As explained on the project website, “at lab scale, energy conversion by perovskite devices was since then rapidly advanced to efficiencies exceeding 20 %. But only few attempts at upscaling have been made, yielding significantly reduced efficiencies below 9 %. In addition, questions about material stability and reliable measurement procedures are still under discussion.” For more information, please see: CHEOPS project website(opens in new window)

Countries

Switzerland