Structuring low-friction surfaces for hydraulic systems

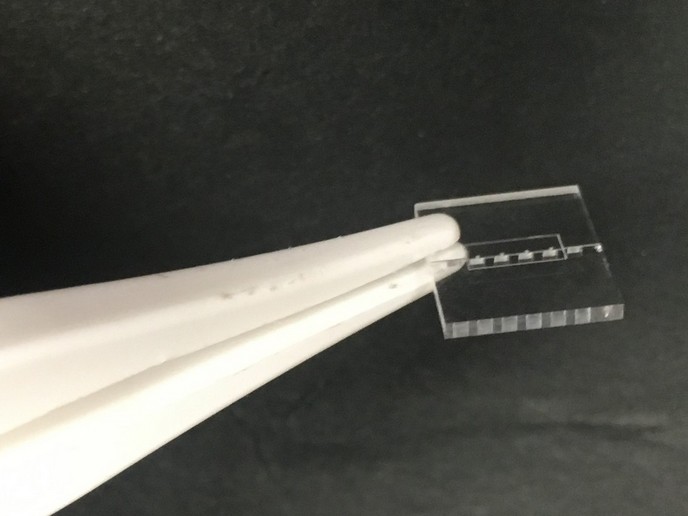

Besides the design of microstructure geometries, new manufacturing strategies and laser systems are required to minimise friction and wear in hydraulic systems. Scientists with extensive expertise in laser technologies, surface preparation and manufacture of hydraulic components joined their efforts to advance the state of the art. With EU funding of the project 'Selective tribological optimisation of fluid kinetics and efficiency by laser surface structuring' (STOKES)(opens in new window), they developed a laser-based process for micro-structuring free-formed surfaces. The focus of their research was on improving the tribological performance of polymer seals used in hydraulic pumps. The STOKES scientists opted for ultra-short–pulse laser ablation as the most suitable surface-structuring technique. A picosecond laser along with a beam-guiding system was installed on a modified milling machine. To control the distribution and alignment of surface structures, they developed dedicated computer-aided design/computer-aided manufacturing software. A series of studies was conducted to determine process limits and optimum manufacturing strategies for a variety of microstructure geometries. The tribological performance of laser-textured surfaces was evaluated with tests on samples at laboratory scale and on real components. A test rig reproducing the actual working conditions of each component was set up for this purpose. The ultimate aim of the STOKES project was to implement laser surface micro-structuring during the forming process of polymer seals and metallic pump components. Press moulds could be laser surface-structured with the proposed approach, offering the possibility to transfer laboratory results to production. Significantly increasing the efficiency and lifetime of hydraulic pumps, it will contribute to the competitiveness of European small and medium-sized enterprises in this sector.