Improved fuel cells for local power generation

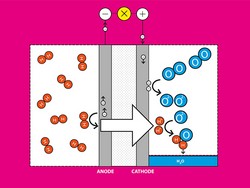

FCs, electrochemical conversion devices that transform chemical energy into electricity, are a promising alternative to the combustion of fossil fuels for many energy applications. The EU-funded project METPROCELL(opens in new window) (Innovative fabrication routes and materials for metal and anode supported proton conducting fuel cells) worked on improving the characteristics of PCFCs while significantly decreasing associated costs. PCFCs are one of the most promising technologies for cogeneration of heat and power (CHP), particularly in small power systems such as micro-CHP, and auxiliary power units (APUs). METPROCELL investigated advanced thin-film ceramic FC technology for operation at intermediate temperatures in the range of 400 to 700 °C. The team developed novel electrolyte and electrode materials with improved properties and low-cost, up-scaled manufacturing processes. The new electrolytes were more tolerant to carbon dioxide and were targeted for the mid-temperature range. Scientists prepared and characterised many new materials largely based on a novel proton conductor that combines high proton conductivity with enhanced chemical stability. Scientists evaluated both metal- and anode-supported FC configurations. They developed half-cells of anode-supported PCFCs based on anode materials developed within the project. Metal supports of eight different ferritic alloys were produced and characterised. The team employed cost-effective manufacturing routes, including co-pressing and electrolyte deposition by spray coating to increase oxidation resistance of anode-supported FCs. For metal-supported FCs, they employed screen printing, electrochemical vapour deposition and thermal spraying. Project scientists optimised materials and methods to produce flat-stack FCs that were demonstrated in two industrial power units, an APU and a gas/micro-CHP. METPROCELL PCFC materials and manufacturing methods are substantially decreasing costs while enhancing system performance for more widespread uptake of this promising FC technology.