Nanostructures increase energy conversion

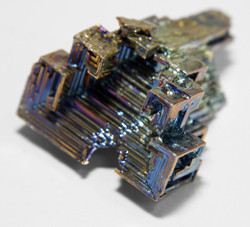

Europe is increasingly threatened by the severe environmental impact of fossil fuel combustion. Being small, inexpensive, lightweight, quiet and pollution-free, highly efficient thermoelectric nanomaterials and devices are expected to provide clean energy technology. The fundamental problem in creating efficient thermoelectric materials is that they need to be very good at conducting electricity, but not heat. The waste heat conversion efficiency in thermoelectrics is governed by its figure of merit (ZT). This number represents the ratio of electrical conductivity and thermoelectric power in the numerator and thermal conductivity in the denominator. The EU-funded project 'Spark plasma sintering nanostructured thermoelectrics' (SPARKNANOTE) sought to create defects and more grain boundaries to decrease lattice thermal conductivity and improve thermoelectric power efficiency. In doing so, the project identified promising optimised compositions, controlled the grain morphology and size, and sintered powders. Scientists produced doped bismuth telluride and cobalt triantimonide by grinding various metal materials and then re-assembling them into bulk samples via spark plasma sintering (SPS). The team found two doping elements for CoSb3 that result in high ZT values. By combining dense nanostructured powder by SPS and a two-step hot forging process, hierarchical nanostructured p-type bismuth-based alloys with the preferred orientation were successfully fabricated. The thermoelectric power in the direction perpendicular to the pressing force was found to be much greater than that of the material sintered via one-step sintering. The second step of SPS hot forging induced interface modifications and crystal defects which produced higher ZT values. Scientists achieved this by more effective phonon scattering which is important in reducing thermal conductivity. As a result, a 50 % enhancement of ZT value in the nanostructured alloys was obtained. The team also introduced nano twin grain boundaries into the materials and then sintered them via SPS, obtaining the maximum ZT value.With materials that are expected to convert a significant amount of waste heat into useful electricity, thermoelectrics could now see more widespread adoption by industry.