Dissimilar materials in nuclear power plants

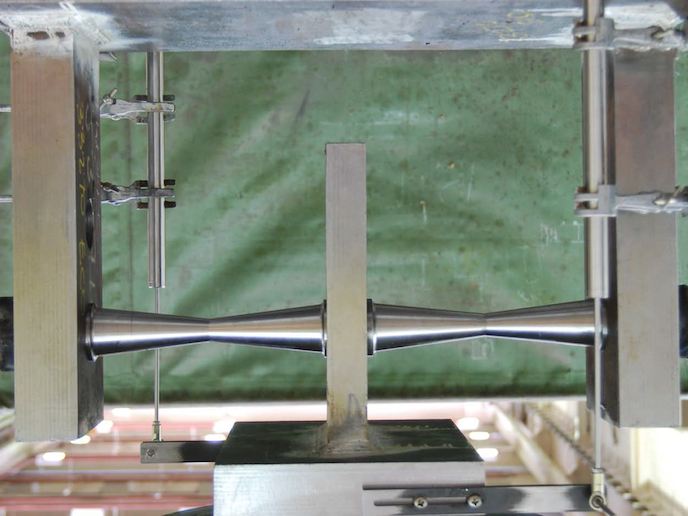

Dissimilar metal welds usually join the ferritic steel pipe nozzles of pressure vessels to the austenitic stainless steel safe-ends. Nickel-based alloys are used as the filler metal in these welded joints because their thermal expansion properties are close to both types of steel. Obviously, maintaining the integrity of such welds in the presence of defects caused by stress corrosion and fatigue is of paramount importance to the safety of nuclear power plants. However, standardised procedures for defect assessments in multi-metallic components are still missing. EU-funded researchers responded to the need for standardisation of integrity and leak-before-break assessments with MULTIMETAL(opens in new window) (Structural performance of multi-metal component). This research project's aim was to improve fracture behaviour investigations despite the inhomogeneity of dissimilar metal welds. To achieve this, the MULTIMETAL team conducted a series of fracture and tensile tests in western and eastern European light water reactors to collect field data from typical welds. Considerable variations in local tensile properties, fracture resistance and microstructures were found. Field data collection was followed by numerical analyses of the structural integrity of sample welds. The state-of-the-art calculations were based on new approaches for micromechanical modelling and the results were supported by extensive laboratory tests on three weld mock-ups. The combination of modelling and, with the results, interpreting experimental data helped MULTIMETAL scientists to develop guidelines for the measurement of different weld material properties. More importantly, a good practice approach was developed that could lead to the harmonisation of fracture assessment processes. Project results did not only fill a gaping hole in material characterisation, they will also help reinforce the competitiveness of the European nuclear energy industry by assisting nuclear power plants to maintain high safety standards.