Flexible composite repair heating systems

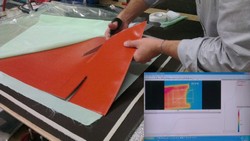

Reliable curing of the patch resin and adhesive layer is essential to ensure the integrity and sound mechanical performance of bonded composite repairs. Improved reliability will contribute to accelerating the use of composites for aircraft structures with distinct advantages in terms of fuel consumption and gaseous emissions. Conventional heating blankets have hitherto been used to conduct heat to the repair area and are controlled by using one or two spots for temperature measurement. This method is relatively simple and provides good results for small repairs. However, large temperature discrepancies – cold and hot spots – are frequently observed when larger areas need to be heated. Within the EU-funded project CONDUCTOR (Flexible conductive composite repair heaters), researchers have developed the technology missing to minimise inhomogeneous temperature distribution. The new conductive skin heating (CSH) solution promises high-quality repair curing for the different dimensions of the patch. The newly developed heating blankets consist of a specially weaved heating fabric encapsulated between two silicone sheets, ensuring electrical insulation. The fabric conducts electrical power in a distributed way over the whole surface of the blanket. In addition, its special weaving allows cutting the blanket in different shapes whenever this is needed. The novelty of the CONDUCTOR technology is the possibility to have a heating blanket tailored to the dimensions of the patch and use it for repairs inside the maintenance line. The user is also able to adapt the shape of the blanket to complex 3D geometries, to distribute heat where it is strictly necessary and, thus, to improve heat management. The CSH – technology based blankets can be mass produced with significant less cost than the standard heating blankets and in all cases, cover or supersede the stare-of-the-art requirements. Consequently, the CSH mats can be much cheaper, and instantly adaptable by the operators eliminating the lead time for a custom blanket fabrication. The CONDUCTOR project's outcome is in line with the targets of the Clean Sky Joint Undertaking regarding the greening of aircraft maintenance that guarantee safe and 'ecolonomic' long-term use of aircraft structures. Through localised heating and much higher overall performance of the CSH method, the time an aircraft needs to spend on the ground for repair should be minimum.