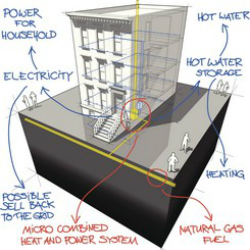

New thermal solution for low-cost heating and electricity in homes

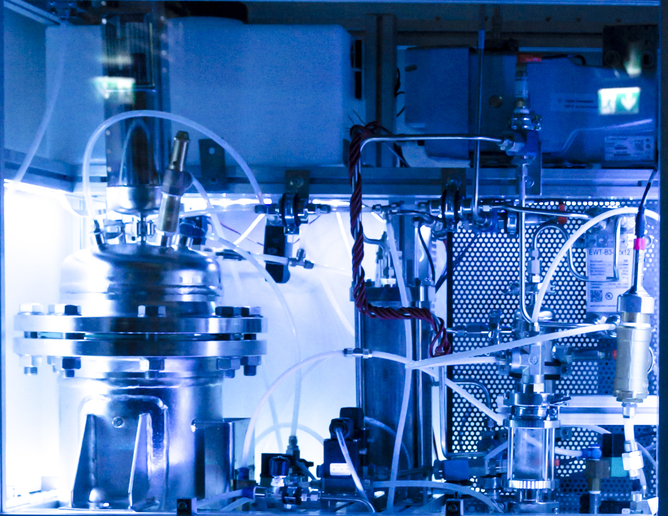

Micro-CHP systems are currently based mainly on internal and external combustion engines. Despite being cheap and efficient, internal combustion engines are able to run only on hydrocarbon fuels, are noisy and hold a short lifetime. Rankine and Stirling engines – both examples of external combustion engines – are complex, expensive and have low thermal efficiency in low-power applications. The EU-funded project UP-THERM(opens in new window) (Innovative high efficiency phase change fluid based heat engine) successfully developed an innovative heat engine configuration that is a viable alternative to the state of the art. Based on an external combustion engine, its novel heat converter does not only require high-temperature heat to reach satisfactory efficiencies, it also exploits low-temperature feedstock that can stem from either natural gas or sustainable sources. Various safe and environmentally friendly liquid working fluids such as water or carbon dioxide are used in the engine. The engine is noiseless and its operation is based on a unique cycle that has the same efficiency as a Carnot cycle. In addition, its extremely simple design allows for enhanced cost effectiveness when considering mass production if compared to the currently available Stirling engines of the same power. UP-THERM's engine is a two-phase engine with a single moving part – a vertical piston – that relies on a phase change of a working fluid to produce reciprocating displacement and sustained thermodynamic oscillations of pressure and flow rate that can be converted to useful work. A major advantage of the newly developed heat engine is that different regenerators can be accommodated. This resolves the problem of engine sealing and piston wear that are both common in Stirling-type engines. The project-developed engine offers a simple and cost-efficient solution that is a competitive alternative option for low-power applications, especially for remote, off-grid areas.