Natural fluids for heating and cooling

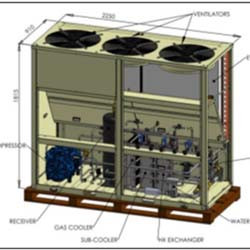

Electrical Heat pumps (HPs) based on the vapour compression cycle have considerably improved in the last decades in terms of efficiency, flexibility and reliability and nowadays they constitute one of the pillars with the highest potential for the reduction of primary energy consumption not only in heating and cooling applications in buildings but also in industrial processes. Despite this, there is still a wide margin for improvement. To become the main contender for heating and cooling applications, heat pumps need to become more efficient, eco-friendly and economical. In regard to their environmental performance, one very important issue must still be solved, i.e. the use of a 0 ODP and very low GWP refrigerants. The EU-funded project 'Next generation of heat pumps working with natural fluids' (NXTHPG)(opens in new window) is taking a big step forward to overcome the barriers impeding widespread use of natural refrigerants. It ushers in a new generation of heat pumps based on hydrocarbons and CO2 that are perfectly feasible and commercially competitive. NXTHPG aims to reach higher efficiency, with a 10-20 % improvement in the seasonal performance factor, while simultaneously reducing the carbon footprint. The target is to reduce the total equivalent warming impact by 20 % compared to state-of-the-art hydrofluorocarbons and hydrofluoroolefins or sorption heat pump technologies. Efforts will be devoted to keeping costs at the same level or slightly higher (10 %), in order to bring a safe, efficient and cost effective new technology to the market. In this direction, five cases or prototypes have been identified (3 for hydrocarbons and 2 for CO2), manufactured and tested by the project members: CASE 1 is a 40kW air to water heat pump (HP) for the production of hot water for heating also covering a low demand of domestic hot water (DHW) with the use of a de-superheater. The unit is reversible on the refrigerant circuit, so providing heating and cooling. CASE 2 is a 60kW geothermal HP for the production of hot water for heating also covering a low demand of DHW with the use of a de-superheater. It is reversible on the refrigerant circuit, so providing heating and cooling. CASE 3 consists of a 50kW HP booster from a neutral water loop, (10-30 ºC) (recovery of waste heat from condensation (25-30ºC) or sewage water (10-15ºC)) up to 60ºC for DHW production. CASE 4 is a 30kW air to water HP for hot water production at 60ºC or up to 80ºC for high temperature applications. CASE 5 is a 50kW air to water HP for heating applications. It targets the renovation market for the replacement of old gas boiler heating systems (5-6 family houses) with high temperature radiators as terminal units. The results of the first experimental campaign are very promising. In the case of prototypes for DHW production, very high HP COPs have been measured, getting values above 5 for CASE 3 (water-to-water HP booster working with propane) and above 4 for CASE 4 (air-to-water HP working with CO2) in most of the working conditions.