New advances in processing of light components

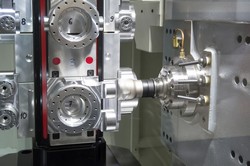

Machining of lightweight and thin-walled components with lower stiffness than similar parts made of conventional materials poses important technical challenges. Vibration sources and excitations during machining can cause surface defects on the work piece. Bad finishes may lead to the need to carry out a final polishing operation on the parts by hand. The EU-funded project DYNAMILL(opens in new window) (Dynamic manufacturing of thin-walled work pieces by milling process) sought to overcome these difficulties. It also aimed to reduce the large number of rejected components by improving clamping devices and damping tools that reduce vibrations, displacements and deformation of the work piece during milling. The end result is a new technology platform that offers complete process planning, new adaptive clamping devices and improved cutting conditions. Process control was focused on high damping and low excitation of work piece vibrations, while planning was strongly supported by cutting-edge software tools. These included finite element method models for dynamic simulations of oscillation and computer-aided manufacturing. Five different demonstrators were carried out, highlighting the broad-sweeping applicability of the platform. The energy sector should benefit from better production of large and medium-sized turbine blades made of a steel alloy. Small turbine blades made of titanium were produced for aircraft. A satellite component, knee bone prosthetic and print media part were also successfully produced. The DYNAMILL platform for control of advanced multi-axis milling of lightweight, thin-walled pieces should have broad-sweeping impact on numerous industries important to the EU economy. Based on results of the project demonstrations: with increased efficiency and accuracy, the system reduces production costs and time by about 15 % and increases process stability by about 30 %. At the same time, power, compressed air and coolants are decreased by up to 30 %, whereas wasted raw materials follow a 20 % reduction.