New technique for reducing heat dissipation in chip stacks

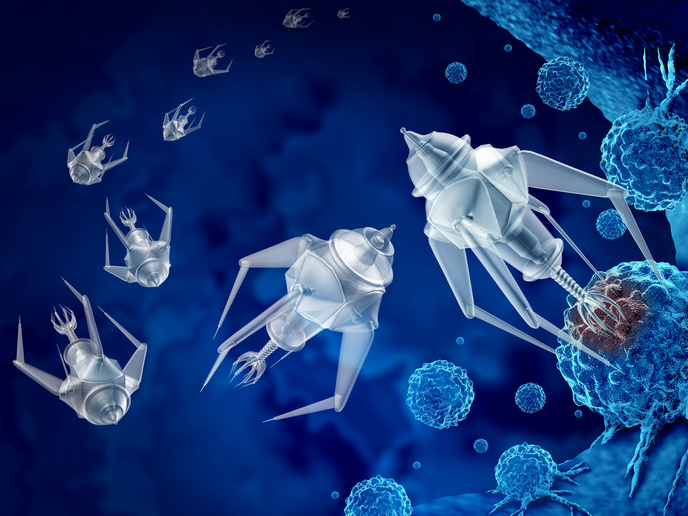

Demands for enhanced functionality in smaller packages at lower prices have driven miniaturisation in the microelectronics sector. Further miniaturisation will require a step change in design, but placing individual semiconductor dies on top of each other requires reliable joining technology to electrically connect them. Integration requires lowering thermal resistance to enable higher interconnect density and device reliability during thermomechanical loading. The lack of such technology and its creation of a roadblock to further miniaturisation spurred scientists to launch the EU-funded project HYPERCONNECT(opens in new window) (Functional joining of dissimilar materials using directed self-assembly of nanoparticles by capillary-bridging). HYPERCONNECT developed a pioneering sequential joint-forming process. Just as the sand needs to be wet to keep the castle construction stable, small water capillary bridges can also keep the chip stacks together. The approach includes injecting nanoparticles in a fluidised bed of micrometre-sized structures to create thermally conductive paths from chip to chip. Evaporation of the fluid containing these tiny nanoparticles causes the nanoparticles to assemble to the contact zones between the larger particles. These resulting necks between the micrometre-sized spheres formed by capillary bridging allow heat to be dissipated more efficiently in 3D chip stacks. Adding a mix of liquid and nanoparticles to form necks that ease the heat transport can be used to stack hundreds of chips on top of each other. This reduces package size and power consumption, while also considerably improving bandwidth. HYPERCONNECT delivered superior multi-material joining technology with a 10-fold increase in thermal conductivity and 5-fold increase in reliability. It enables novel 3D stacked chip architectures, paving the way to continued miniaturisation and putting the EU in the lead of an economically important race.