New materials for fuel cells for cars

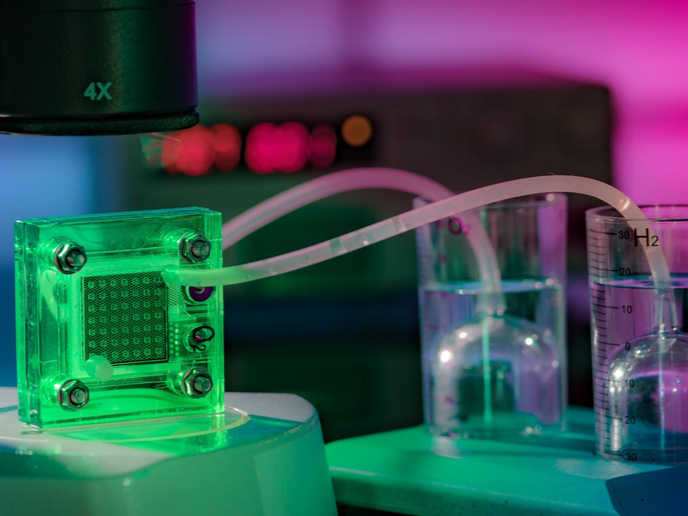

Fuel cells are widely considered to play an important role in the vehicles of the future. The technology could be complementary to electric vehicle development by helping to significantly extend their range. However, power density, cost and durability are still key challenges for market introduction. The EU-funded project IMPACT(opens in new window) (Improved lifetime of automotive application fuel cells with ultra-low Pt-loading) responded to these challenges by improving the membrane electrode assembly (MEA) – the core component of an automotive fuel cell. Project partners succeeded in developing MEAs with ultra-low Pt loading of below 0.2 g per square centimetre. Scientists’ efforts for improving the long-term stability of these catalysts proved successful as fuel cell stacks still went strong after 5 000 hours, with degradation rates below 10 μV per hour and MEA power density of 1 W per square centimetre. The team successfully increased the electrochemical stability of the anode catalyst in different operating temperatures and humidity-level ranges. Use of a Pt-cobalt cathode electrocatalyst helped achieve project targets set for MEA performance and stability. To increase cell performance, partners developed 10-μm-thick membranes that were also chemically stabilised to ensure high resistance against corrosion and reduced hydrogen cross-over. Further effort was dedicated to developing ionomers for the catalyst layers. Understanding degradation processes that apply to such MEAs and the relationship between degradation, lifetime and Pt loading were essential to achieve project aims. Thanks to detailed ex situ and in situ analysis of the newly developed materials, the team obtained better understanding of degradation mechanisms. IMPACT contributed to further improving the durability of MEAs with low Pt concentrations at typical automotive operation conditions. The delivery of low-loaded MEAs is essential for widespread commercialisation as Pt makes up a large part of the cost of this component.