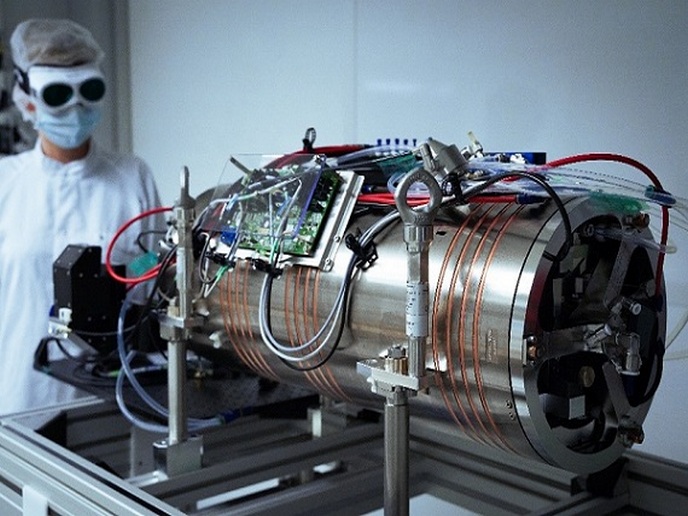

Innovative textile spinning unit

In INNOVATIVE SPINNING (Small single drives and magnetic bearings in spinning machines), scientists adopted a multidisciplinary approach for designing and developing a mechatronic system that should set a new standard for next-generation rotor spinning machines. The concept involves combining rotor spinning with an active magnetic bearing that works on the principle of electromagnetic suspension. A high-efficiency brushless direct current motor transfers power to the innovative disk-shaped suspended rotor spinning. A motor controller senses the rotor position and orientation relative to the stator coils through sensors. Following literature reviews, scientists conducted numerical simulations and modelling supported by experimental verification. Based on these, they successfully managed to overcome challenges related to the mechatronic system design. These mainly included developing a reliable sensing system, integrating the spinning rotor into a sophisticated compact system and optimising the spinning process to improve yarn quality. A great project achievement was a 30 % decrease in mechanical energy losses because of no mechanical friction between the magnetic bearings and the rotor. Eliminating the process complexity, the newly developed spinning unit holds great promise for producing high-quality yarn. INNOVATIVE SPINNING introduced technology advancements in rotor spinning that should retain the European industry's competitive edge against its Asian counterparts.