New fibre lasers for cutting thick metals

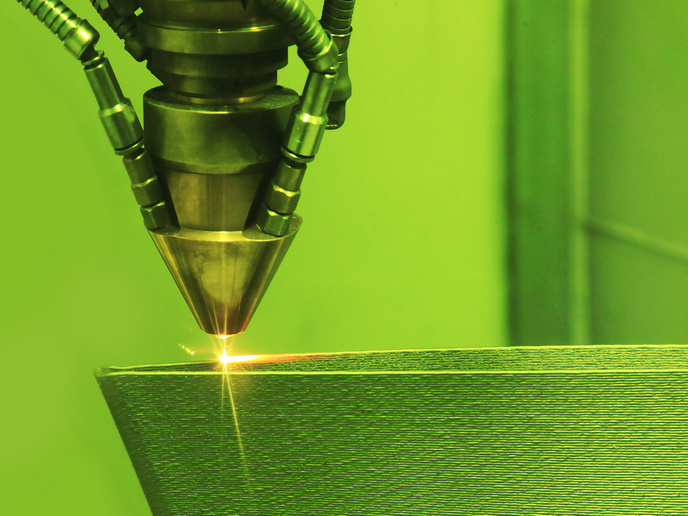

Fibre lasers are ideal for cutting and etching metals of various thicknesses and compositions. What makes them valuable for industry is the use of a coherent laser beam that allows much energy to be concentrated on a small spot. This promising technology boasts several advantages in terms of wall-plug efficiency, flexible processing, low maintenance and high cutting speeds. However, the technology leads to poor cut quality on stainless steel and non-ferrous metals when material thickness exceeds 3 mm. The FILCO(opens in new window) (Fibre-delivered laser cutting optimisation) project delivered an innovative product that has the potential to revolutionise commercial laser cutting. Project members successfully produced a 1-micron laser cutting head capable of processing up to 12 mm-thick stainless steel. This innovative cutting head does not only improve cut quality compared to conventional fibre laser systems, it also cuts faster compared to CO2 laser systems. This achievement was the by-product of innovative developments in laser beam optics and gas nozzles. The newly developed beam forming unit can adjust the beam focus to maximise laser light absorption in the material while also ensuring homogeneous irradiation. The gas entering the nozzle moves at supersonic velocities, thereby improving extraction of the molten material out of the kerf. The innovative cutting head is flexible enough to be included in existing or new systems and can lead to a 15 % increase in productivity. The FILCO system also meets industry requirements for more compact and safer design of laser cutting heads. Over the last few years, 1-micron cutting lasers have faced an unprecedented surge in demand, accounting now for 30 % of fibre lasers in the market. From 2010 until now, the number of suppliers has also significantly increased, with most of them stemming from countries in the Far East. The FILCO innovative product should keep Europe at the forefront of efficient cutting of thick metals with fibre laser optics. Watch the project video here(opens in new window).