New applications for membrane technology in the chemical industry

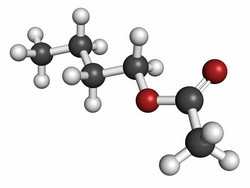

PMRs integrate the reaction and separation steps in industrial chemistry to dramatically improve reactor performance. They have been successfully applied to equilibrium-limited reactions involving water as one of the side products. However, the feasibility of this approach has not yet been explored for reactions yielding an organic product such as methanol or ethanol. The NEW-PMR (New frontiers in (trans)esterification pervaporation membrane reactors) project was established to provide a scientific basis for the production of organic by-products using PMRs, based on the reaction between butanol and methyl acetate to produce methanol and butyl acetate. Moreover, the study was extended to other transesterification reactions such as the reaction between methanol and ethyl acetate to produce ethanol and methyl acetate, which is a reference reaction used in the production of biodiesel. Experimental results with commercial membranes showed that some membranes were capable of separating butanol from the reaction medium due to greater permeability of this component through the membrane. Using these membranes on an industrial scale would significantly reduce the separation energy. Researchers integrated pervaporation into conventional processes in combination with distillation and as a stand-alone technology. It was estimated that the use of pervaporation to perform the separation of methanol-methyl acetate resulted in energy savings of over 90 % when compared with distillation. The integration of membrane technology to give a pervaporation-distillation hybrid demonstrated the possible advantages of such a design and the development of a more environmentally friendly process. In addition, guidelines were developed to ensure selection of the most environment-friendly treatment depending on the composition of the liquid mixture.