New lithography technique breaks resolution limits

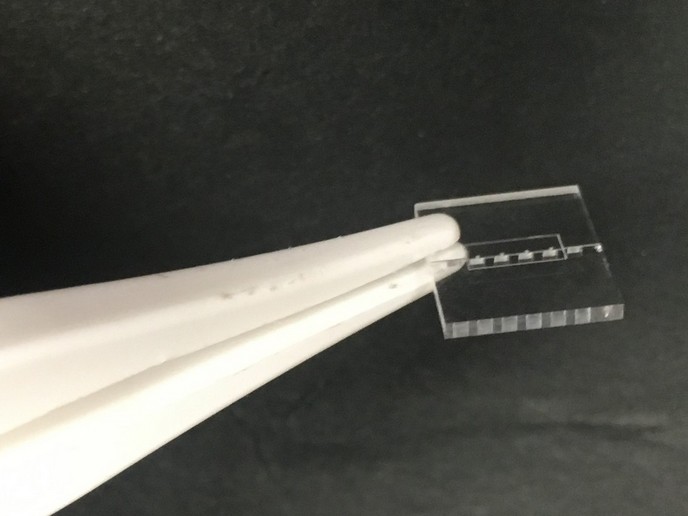

According to Rayleigh's scaling laws of resolution, diffraction effects limit the ability to project a clear image of a small feature onto a wafer to half the wavelength of the light used. In the case of photolithography, silicon wafers and patterns are written with a light-sensitive polymer called a photoresist. Use of laser radiation enables non-contact surface structuring with high temporal and spatial resolution. The energies and intensities provided by ultrashort laser pulses can lead to very rapid localised heating, high thermal gradients, and fast subsequent cooling and re-solidification rates. Generating clear and well-defined nano- and microstructures with conventional photolithography techniques is difficult for a lot of reasons; controlling the photoresist density, intensity distribution and substrate topography can all combine to make it a challenge. EU funding of the project LILAC (Laser-initiated liquid-assisted colloidal lithography) enabled the development of innovative low-cost technology with amazing resolution. Scientists applied an innovative colloidal lithography technique called laser-initiated liquid-assisted colloidal lithography to control patterning of 3D nanostructures over a wide range of surfaces. This technique relies on using colloidal crystals as masks for etching and deposition, allowing fabrication of various nanostructures on planar and non-planar substrates. Scientists succeeded in controlling light into complex distribution patterns beneath a colloidal particle by immersing surface-supported particles in different liquids. Processing with single, intense laser pulses yielded complex 3D patterns on silicon and gallium arsenide substrates. The newly developed technique involves a complex interplay of laser light scattering by the colloidal particles, the liquid medium and the substrate – all of which can be varied and controlled by the user. These characteristic fingerprints open the way towards achieving sub-diffraction limited patterning of the surfaces of a wide range of materials. Nano-patterning of surfaces with this colloidal lithography technique is a complementary way to conventional top-down lithography. LILAC expects that this technology will enable a broad range of new nanoscale applications, including biosensing and nanophotonics.