Large scale ceramics machining

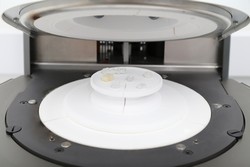

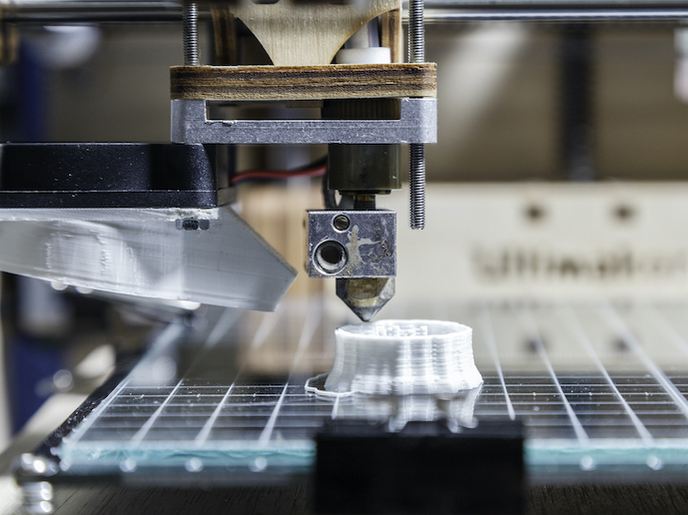

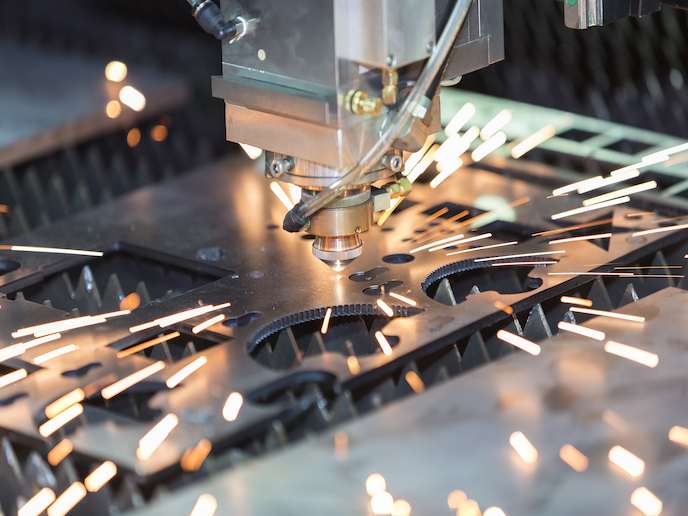

For myriad industrial applications, where most materials fail, technical ceramics can be used thanks to their hardness, thermal stability, chemical and wear resistance. However, these superior properties also make it difficult to machine ceramics into a finished shape. On a laboratory scale, it is possible to produce new ceramic composites using spark plasma sintering. Electrically conductive powders are pressed into blanks through a combination of Joule and inductive heating. The aim of the EU-funded project HYMACER(opens in new window) (Hybrid sintering and advanced machining of technical ceramics) was to scale up the process for the manufacture of large blanks. SMEs in the consortium covered each part in the entire chain from the production of blanks of ceramics to the manufacturing of finished parts. Starting with the sintering furnaces, HYMACER partners could support the production of blanks up to the machining of large blanks into smaller parts. They were also joined by research and development partners to implement new knowledge. Research focused on industrial machining technologies for electrically conductive ceramics and specifically, aluminium oxide- and zirconium dioxide-based composites. Project partners worked on the optimisation of synthesis of selected raw materials as well as their processing in a hybrid spark plasma sintering-hot pressing system. A first, the HYMACER team successfully fabricated dense blanks of new ceramics with diameters ranging between 150 and 400 mm and thicknesses up to 32 mm. Numerical modelling and simulations proved to be crucial for gaining fundamental knowledge of the new hybrid technology. Moreover, they obtained know-how for further development and optimisation of the available equipment.