Microfluidics for mass-produced custom nanoparticles

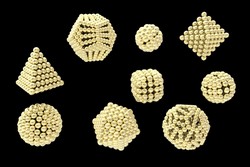

Microfluidics – the science and technology of manipulating nanolitre to picolitre volumes of fluids in micro-scale channels – is a multidisciplinary field at the intersection of engineering, physics, nanotechnology and biotechnology. This rapidly growing field aims to tackle challenges related to fine-scale manipulation of small particles. Size and shape, surface, self-assembly and reproducibility are fundamental to nanomaterials. Conventional batch-type bulk reactors are limited in their ability to reproducibly prepare high-quality custom nanoparticles. Within the EU-funded project PLATFORM2NANO (Development of a microfluidic platform to produce nanomaterials and assessment on new nanotechnology applications), scientists came up with a new way to synthesise nanoparticles, transforming the conventional batch-by-batch process into a larger-scale assembly line. Experimenting with highly versatile polymer, glass and stainless steel microreactors, the project team successfully produced complex gold-based nanostructures of well-defined shapes and sizes. Cobalt nanoparticles were first used as a template and then were replaced with gold nanoparticles that led to the formation of a hollow structure. The team then introduced chemical functional groups to the gold surfaces to improve biocompatibility and sterilised them with ultraviolet light. The production rate of the microfluidic reactors used far exceeded that of the conventional batch reactors. The resulting custom hollow gold nanoparticles can find use in photothermal therapy, improving cancer diagnosis and treatment. Understanding how facets develop on nanocrystals is critical to controlling their shape, which in turn allows control of the crystals’ chemical properties. Using gas-segmented flow reactors, scientists deployed flow reactors based on gas reactions that allowed control of the shape of nanocrystals as they grew. Considering the important role of polymer nanoparticles in smart drug delivery, the team successfully produced uniform polymer nanoparticles that can effectively deliver therapeutic agents into the diseased tissue. Until now, fine-scale manipulation of nanoparticles was a major challenge in the field. Microfluidics plays a key role in nanoparticle synthesis, enabling precise control and large-scale production of small particles.