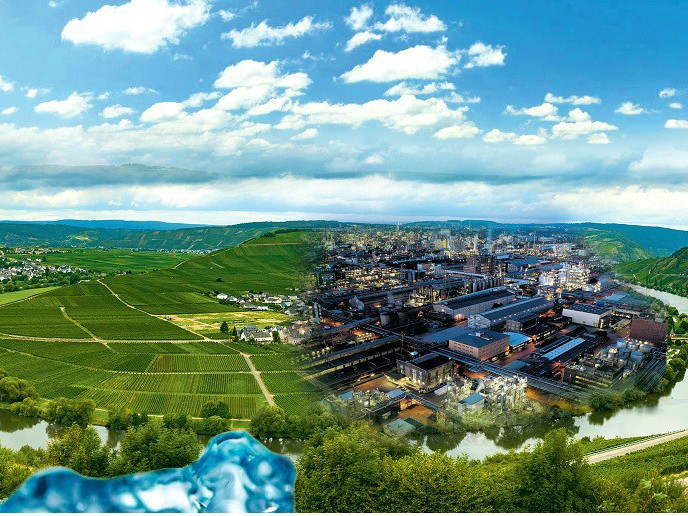

New separation technologies will join Europe’s process industry and nature

PRODIAS(opens in new window) project coordinator Prof. Michael-Helmut Kopf gets straight to the point: “Sustainable, competitive process industry and respect for nature is not a contradiction!” Issues burdening this industry centre on introducing renewable raw materials into existing value chains and developing related cost- and energy-efficient water removal, product-recovery and purification techniques. “A re-thinking of downstream processing is indispensable,” he notes. “This includes new/optimised separation technologies as well as suitable methodologies for fast-track development of tailored downstream processes.” Industrial biotechnology The project accomplished its two main goals, one being to decrease production costs for renewable-based products. The other was to simultaneously reduce the environmental footprint of the processes employed via decreased energy consumption and increased raw material efficiency. Consortium members covering both industry and academia collaborated to successfully improve and optimise methods and technologies for processing diluted aqueous systems originating from white biotechnology processes. PRODIAS managed this by leveraging industrial biotechnology. This technology can be used to enable the production of complex performance products such as enzymes and chemical value chain intermediates based on renewable resources. Wide-ranging impact Specifically, partners developed four demonstrator units and several R&D standards. “These are now ready to be used in lab- and commercial scale,” reports Prof. Kopf. One demonstrator covers low-energy, high-performance disc-stack centrifuges for biomass separation and another involves freeze concentration to be used for thermo-sensitive dissolved compounds (e.g. enzymes). Another two are a novel SMB-EBA combination as a hybrid process including advanced control software, and high-performance (titre) fermentation of small organic pre-cursor molecules. Relevant to R&D standards is combining extraction/IEX & bi-polar electrodialysis to purify chemical value-chain molecules produced by fermentation. Another is NEAT, a novel analytical method using NMR spectroscopy to predict thermodynamic properties of unspecified mixtures, which is relevant for downstream processing in many fields of process engineering. Beyond white biotech applications, these achievements are beneficial for many sectors of Europe’s process industry. For example, the professor explains, “low energy centrifuges can be used in various applications within chemical processing, pulp and paper, water management and food processing.” Fruitful cooperation Prof. Kopf believes the PRODIAS slogan “One Goal, One Project, One Team” facilitated project successes. “Besides the great achievements in terms of apparatuses and method optimisation, the smooth and successful cooperation of the nine partners was a unique and encouraging experience.” The project’s set-up was also a key factor, he underlines. The structure of most work packages required the cooperation of at least two partners to fulfil the tasks. This demanded and supported intense discussions as well as early identification of potential conflicts of interest. The Chemical & Engineering Technology journal’s PRODIAS Special Issue(opens in new window) is testament to the spirit of the project team. According to the professor, it highlights “the achievements of fruitful cooperation of academia and industry and outlines potential future R&D work triggered by PRODIAS.” Next steps One of the next steps needed to harvest the benefits of project results, Prof. Kopf outlines, is integration of the respective apparatuses and methods in future related projects. “Many of the PRODIAS-established partnerships will continue and in future contribute to further increase the competitiveness of renewable-based products and processes,” he concludes.