New models help create stronger and more ductile metal alloys

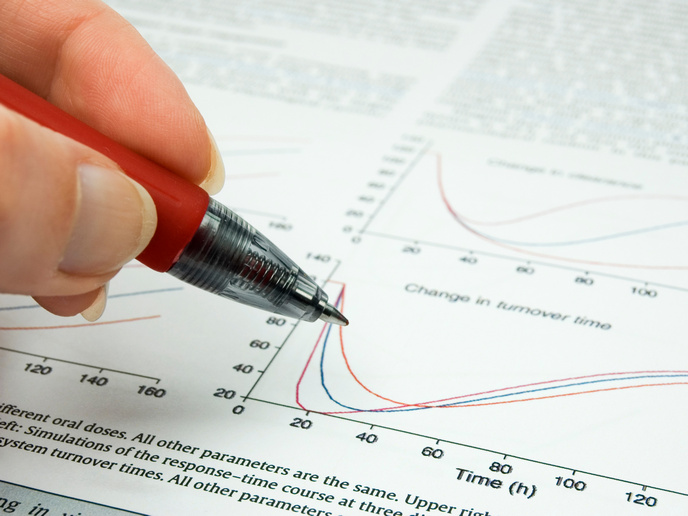

Computer models are increasingly being used in a number of industries to assist in evaluating product performance, the material synthesis and selection processes, as well as material fabrication into components. Testing material properties is not simple, as the underlying phenomena extend across a vast range of length and time scales. Combining information at the quantum, atomistic, mesoscopic and macroscopic levels is vital for developing multi-scale models that describe and even predict material behaviour. Metallurgists have introduced a great variety of new alloys over the last 60 years. “Developing new or better metal alloys relies crucially on thoroughly understanding the fundamental physical phenomena underlying their impressive properties, or conversely, factors that negatively impact their properties. Due to the complexity, the field has only seen incremental improvements to existing alloys or serendipitous improvements from materials that are developed experimentally,” notes Professor Bill Curtin, coordinator of the EU-funded PreCoMet project. Project research successfully uncovered important physical phenomena affecting the strength and ductility of certain metal classes. The path to more ductile magnesium alloys In its pure form, magnesium is hard to stretch and form, and also lacks sufficient strength for many structural applications. PreCoMet researchers focused on identifying the atomistic origins of this unusual behaviour. Simulations of magnesium interactions at the atomic scale helped them establish a picture that unified decades of experimentation on the material’s macroscopic property. “The key atomistic defects, called dislocations are the ‘carrier’ of plastic deformation; they allow neighbouring crystal planes slip over each other. However, we noticed an unusual behaviour when studying the structure of an important dislocation, which started morphing into several possible geometries that locked it in place so that it could not move. These new structures had been observed experimentally before but they were considered to be experimental anomalies,” explains Prof. Curtin. Researchers showed that this immovable structure is intrinsic to magnesium and accounts for its low ductility. The team then found that adding rare-earth elements such as yttrium, neodymium and gadolinium even at low concentrations substantially increases the number of moveable dislocations and therefore enhances magnesium’s ductility. Using their models, the team predicted new alloys with good ductile properties, avoiding the use of the less-desirable rare-earth elements. Taking the guesswork out for new high-entropy alloys Consisting of multiple elements, the new class of high-entropy alloys are highly sought after, amongst others, for their high strength and high fracture resistance over a wide range of temperatures. Despite 70 years of experiments, there have been no models that could accurately predict alloy strength in even simple structures where a single element dominates. Researchers extended their work towards modelling alloy classes having two common crystal structures, independent of the number of elements as well as their concentrations. Using their models, they can successfully predict the strength of many alloys based on some fundamental atomic properties. “We can now design new high-strength alloys that have never been made before. Given the sheer number of possible composition combinations, this is a major feat, as it is difficult for material scientists to know where to look for new high-entropy alloys,” concludes Prof. Curtin. The project work could help engineers develop special alloys for a wide range of applications from the aerospace and automotive to the biomedical industry.