Riblets on wind turbines help them go with the flow more efficiently

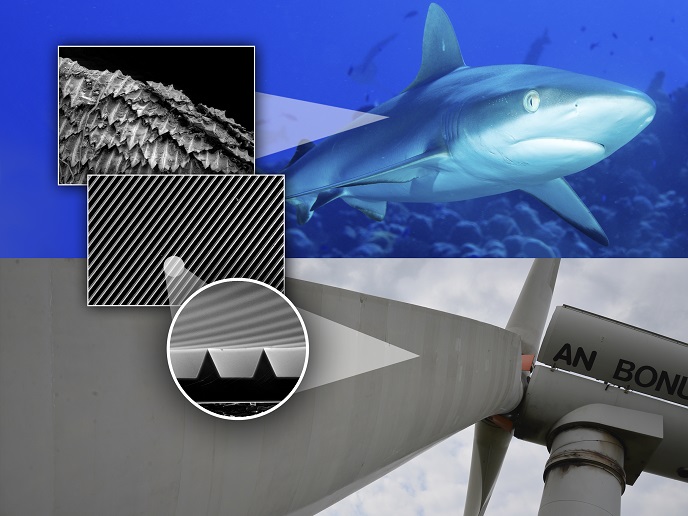

Fast-swimming hunting sharks like the great white have a unique adaptation on their scaly skins to reduce drag, enhancing energy-efficiency and speed. Tiny ‘riblets’ on each scale smooth the flow of water, reducing turbulence and energy loss. Aerospace engineers have been interested in riblets since the 1980s leading to important technological advances. The EU-funded Riblet4Wind(opens in new window) project set out to transfer proven riblet technology demonstrated in the aerospace sector to increasingly important applications in renewable wind energy systems.

From sharks to airplanes to wind turbines

Riblet4Wind engineers began with a previously developed riblet coating and automated single-step application technology. According to project coordinator Dorothea Stübing, “Prior to Riblet4Wind, wind tunnel experiments had shown that airfoils equipped with this riblet coating exhibit improved aerodynamic performance, increasing the glide ratio by up to 30 %. In-flight testing of riblet-structured coating patches and comprehensive investigations of the influence of ageing and wear on aerodynamic performance corroborated the technology’s potential.” Just as different sharks have different riblet ‘specs’ to meet the sharks’ requirements, airfoil diversity requires tailored riblet design for maximum impact. This necessitated development of novel aerodynamic simulations of riblet-coated wind turbine blades to determine the optimal riblet dimensions as well as location on the blades for the greatest benefit. Riblet4Wind scientists also had to modify the materials and processes to realise the designs. With the required technologies under their belts, researchers were ready for a full-scale demonstration on a wind turbine.

Overcoming obstacles, exceeding expectations and planning a path forward

The path to implementing innovations can be rocky. Various obstacles were met which led to suboptimal conditions for demonstrating the technology. One critical challenge was the necessity of relying on a 20-year old wind turbine to demonstrate the technology and its benefits regarding increased energy production. Despite these obstacles, Stübing points out, “We were able to successfully apply the riblet coating on three rotor blades – and with this achievement we surpassed progress within the aeronautic industry – and monitor the impact on performance during nine months in operation. The aerodynamic work carried out within the project significantly exceeded the planned tasks.” Extensive wind tunnel experiments with riblet-coated blade profiles provided a profound knowledge base regarding the influence of riblets on the aerodynamic behaviour of the blades at different angles of attack. Riblet4Wind is now in the process of exploring opportunities to test the technology on a modern wind turbine at a wind farm research site equipped with measurement and power performance infrastructure. The upcoming tests will provide the opportunity to prove the reliability, enhanced power output and reduced noise emissions of riblet-coated turbine blades in a state-of-the-art system. The data will be invaluable in facilitating market up-take and commercialisation. In the meantime, the partners are moving forward with business plans for commercialisation of the individual technologies developed within the scope of the project. Stübing summarises, “Nature evolved exciting solutions for all sorts of problems and with our current technological capabilities we are able to successfully transfer them to technical applications.” The refined models and enhanced coatings are expected to have important impact on airfoil development in the aerospace and wind energy sectors and beyond.