An AI-powered platform for predictive maintenance solutions

The EU-funded project SERENA(opens in new window) (VerSatilE plug-and-play platform enabling remote pREdictive mainteNAnce) is at the forefront of the AI revolution in industry. Specifically designed for manufacturing, its platform is based upon four key technologies: remote condition monitoring and control, AI condition-based maintenance, augmented reality-based tools for remote assistance and human operator support, and finally, a cloud-based platform for versatile remote diagnostics. “In summary, we have developed a distributed, lightweight and scalable industrial internet of things (IIoT) platform which, through the collective use of its integrated services, will provide predictive maintenance solutions to ‘shop floor’ personnel,” says Massimo Ippolito, SERENA project coordinator.

Industrial challenges

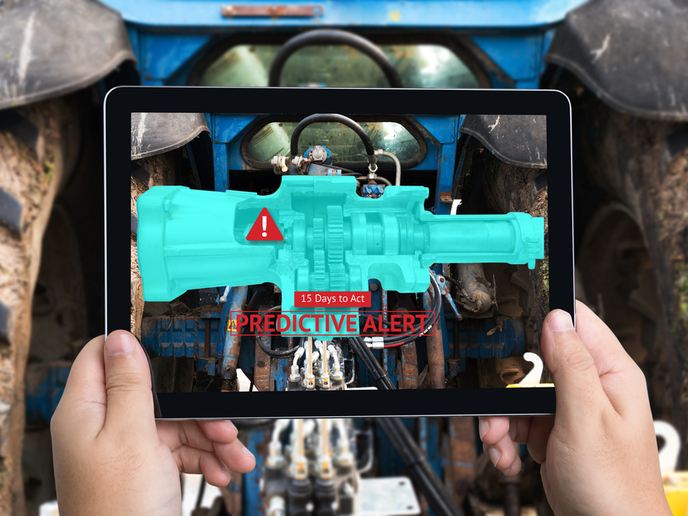

The platform uses a lightweight micro-services architecture, utilising Docker containers to wrap the offered services into deployable units. The AI components for predictive analytics, both distributed and centralised, are used for estimating potential failures in manufacturing equipment, allowing for the planning and scheduling of maintenance activities in a specific time frame. This ensures that the production within the factory is not interrupted by unexpected downtime. On top of this, the SERENA system facilitates remote support by maintenance personnel using VR and AR-based technologies, helping them assess the status of machinery and overall equipment within the factory. This functionality is accessed through the use of smart glasses, smartphones and tablets. It wasn’t always plain sailing for the project team. “It became evident from the first phases of the project that predictive analytics is a matter not only of data availability but of data of the proper quality as well,” explains Ippolito. “If the data does not contain the features that correspond to the potential failure of equipment, then it is of no use.” In addition, there is no single rule for every case, with human analysis often required. “Nevertheless, SERENA moved a step beyond those limitations by introducing a self-assessment mechanism and a methodology that could potentially be generic enough to capture a variety of problems,” Ippolito adds. Finally, another set of challenges encountered and conquered was the need to deploy the SERENA system in versatile environments with different connectivity capabilities and legacy systems. The SERENA system is designed to support many versatile cases and can be deployed via the cloud or physically on the premises.

Looking to the future

Regarding the future, Ippolito strongly believes that overall, now is the time that commercially viable AI-based solutions will gradually begin to filter through onto the market. “In the future, it is expected that AI applications will keep extending into new areas providing interpretable results of increased accuracy and reduced response time,” he remarks. Ippolito adds that developers should always consider the ethical use of this technology: “AI should have a positive impact on society and the environment, and in some cases, this might not be as easy or as obvious as it sounds.” Since the project’s conclusion in March 2021, consortium partners have continued to build on SERENA’s innovations to introduce them onto the market and into industrial practice. In the meantime, the SERENA book, a joint dissemination activity by the entire consortium, has been published. Alongside this, the ForeSee(opens in new window) cluster (which SERENA belongs to) has finalised a roadmap on predictive maintenance with key findings of the research now being carried out. Further developments are currently being undertaken by both industrial and academic partners. “Whilst the SERENA project has finished, project members are still working together but also individually to make sure that SERENA’s legacy will last for a long time to come,” concludes Ippolito. “This will generate positive effects on each consortium partner related to predictive maintenance projects as the new competences will allow them to more fully leverage their internal and external exploitation experience.”