Simulating microwave composite processing with unprecedented accuracy

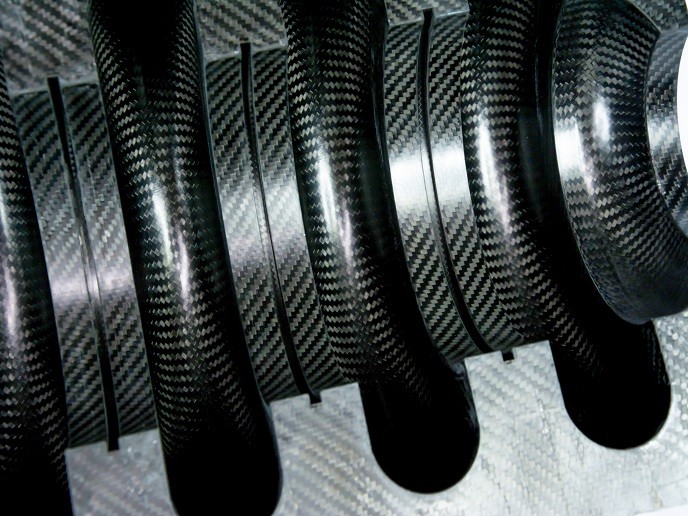

Composites are materials made from two or more constituents with different properties. They have enabled significant reductions in weight, increases in specific strength, and improvements in thermal and electrical conductivity relative to conventional components in numerous applications. Fibre composites have complex properties relating to the preferred orientation of the fibres and fibre length relative to diameter (aspect ratio). This anisotropy (having different properties along different axes of measurement) together with their high aspect ratios makes them difficult to model. The EU-funded SIMUTOOL(opens in new window) project has developed a holistic simulation platform for composite manufacturing via microwave heating that overcomes the challenges and delivers results.

Hitting the spot, quickly and efficiently

Composite manufacturing relies on embedding reinforcement in a matrix, which requires heating the resin matrix, to cure the thermoset resin (create cross-links) in melted thermoplastic resin. Methods such as hot-press, autoclave, or the use of a conventional oven are based on conduction and/or convection, where a bulk tool and/or the surrounding air must be heated first, wasting time and energy. Microwave volumetric heating selectively targets the system to be heated and does so instantaneously throughout, promising significant energy savings and more sustainable composite production, but new methods are required for better process simulation.

Inside the black box

Commercially available tools can simulate electromagnetic fields, but they do not address the fine compositional details and properties of today’s composites. Project coordinator Jasmin Stein of TWI Ltd(opens in new window) says: “The SIMUTOOL simulation platform includes an electromagnetic field coupled with heat transfer mechanisms that take place during the production process. Further, we have designed and built a ceramic matrix composite tool with a durable microwave-absorbing layer so that the bulk of the tool is transparent to microwaves – the heating is directed at the composite part and not the whole tool. Finally, we integrated the microwave heating process with automated fibre placement technology.” SIMUTOOL couples ESI’s electromagnetic solver(opens in new window) with heat transfer and resin transfer moulding(opens in new window) solvers, opening new application domains and improving the accuracy of analysis and is generally applicable to microwave heating problems. Accurate simulation of mixed-scale electromagnetic problems relevant to composites is accomplished by coupling with a finite element method (FEM)-based proper generalised decomposition(opens in new window) solver.

A hot idea exceeds expectations

Stein summarises: “Using parallelisation and optimised solvers to overcome the challenges associated with the massive amount of data, we have demonstrated the feasibility of full-wave, broadband simulation of low-loss large microwave cavities, something not previously possible due to the computational effort. Combining this with a parameterised model for real-time process control is an important achievement.” Current experimental trials demonstrate energy savings greater than 50 %, surpassing original goals of 30 % relative to conventional methods. Project outcomes are currently being exploited by individual partners and a Phase II project is in the works to increase the technology readiness level. Future directions include accelerating production times while enhancing digital technologies to accommodate even greater process detail. The global advanced polymer composites market is expected to reach USD 16.83 billion by 2025(opens in new window), largely propelled by the aerospace and automotive sectors. SIMUTOOL should help deliver optimised products sustainably while supporting the use of microwave technology more generally.