Novel engineering platform uses AI to automate electronics engineering

An embedded system(opens in new window) is one in which a computer is integrated within a product and responsible for monitoring or regulating functions. Embedded systems can be found in a huge range of everyday electronic devices and products, including medical devices, airplanes, cars, fridges, TVs and mobile phones. They now typically run on microcontrollers, rather than the simple microprocessors of the past. While embedded systems have helped drive technological progress, a common engineering limitation is the slow speed of design and development. It currently takes an electronics engineer around 3 weeks to design a basic printed circuit board(opens in new window) (PCB) layout, resulting in less real innovation time. Celus(opens in new window), which hosted the EU-supported Contunity project, has developed a solution which enables electronic engineers to generate embedded systems much faster, without the specialist knowledge currently required. “Our artificial intelligence generates embedded software code, hardware schematics and PCB layouts. By taking over the repetitive and dull optimisation work, our platform allows engineers to refocus on real problem-solving tasks,” says Nicole Lontzek, spokesperson for Celus.

Empowering dreamers and developers

The Contunity team started by analysing the workflow of electronics engineers to identify bottlenecks and work which, rather than introducing real value, actually stifle innovation. “You could compare our approach to software development. In the early days, developers had to first write, then repeatedly check, lines of code to create very basic webpages. Now we have modular systems for web design which anyone can use. This is what we did for electronics engineering,” explains Lontzek. The Celus software is based on machine learning(opens in new window). After being fed large amounts of data, the software applied predetermined rules to that input and so ‘learned’ to continuously improve on its completion of tasks. When developing elements of the embedded systems, such as the PCB layouts, once a solution was found for design problems the system generated a new training dataset for future reference. The flexibility of this modular solution means that it can optimise the sizes of PCB layouts. It can also customise elements and select parts from a pre-existing library, to generate entire hardware schematics. This means development teams can now build embedded control units without in-depth knowledge.

Integration as investment

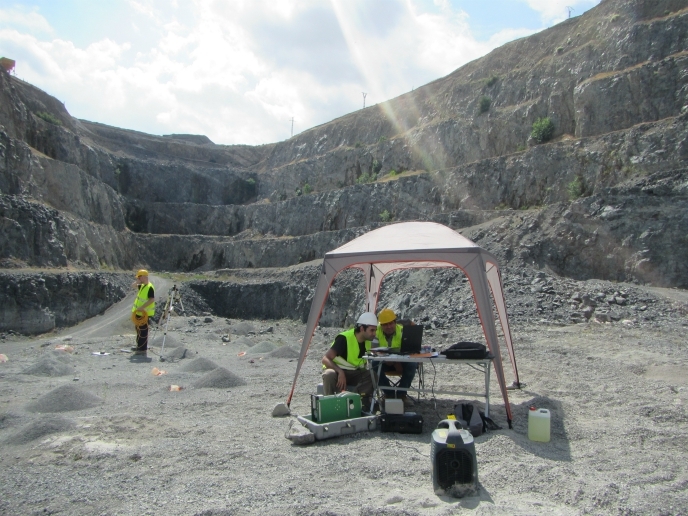

Celus conducted several tests and have a number of pilots currently running. For example, the team developed wearable technology with environment-sensitive light emitting diodes (LEDs). Some 100 components were needed to achieve this, with over 1 500 connections. Such products are heavily dependent on user feedback, so it is important to iterate prototypes quickly. The Celus solution enabled the development team to add and remove sensors and LEDs from designs at the click of a button. “We reduced development time from 80 hours to 2 hours. Time savings like this equate to financial savings for companies in highly competitive markets,” adds Lontzek. The Celus solution can be integrated as seamlessly as possible into common computer-aided design tools. For other systems and workflows, while the system is not yet capable of a plug and play integration, it is designed to be straightforward and is supported by Celus. Initially, Celus will focus marketing efforts on Austria, Germany and Switzerland in Europe, and on the United States, but the software is already available globally to any interested electronics engineering companies. Looking to the future, the team are currently fine-tuning some workflows and developing APIs to make the platform even more accessible.