Sustainable polymers for 3D-printed batteries

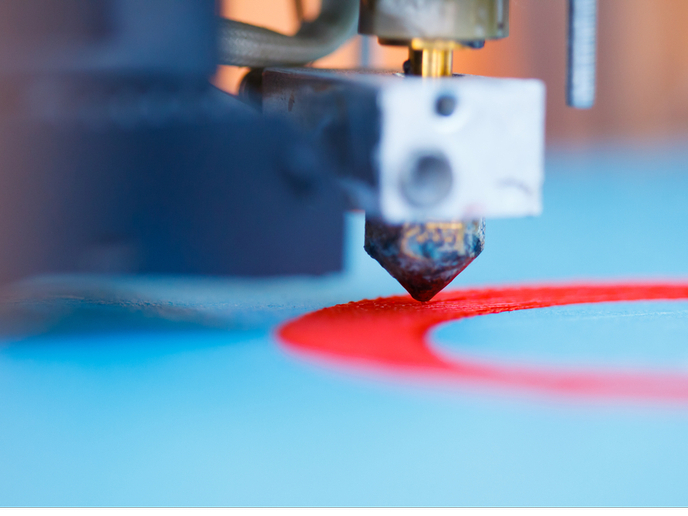

Start-up company POLYKEY was created in 2020 as a spin-out of the University of the Basque Country. Besides specialising in plastic recycling through depolymerisation, it also proposes a new generation of solid-state batteries built from sustainable polymers. The promise is tantalising: the new batteries are lighter, perform better at high temperatures and are not flammable. The venture initially started in 2012 with the ERC Starting Grant iPES project, followed 2 years ago by ERC Proof of Concept (PoC) project iPES-3DBat (Innovative Polymeric Batteries by 3D Printing). Concerned with the limitation of current batteries with regards to shape, rigidity and cost, the project team led by David Mecerreyes first developed a range of new polymeric materials. Then, with iPES-3DBat, they set out to produce polymer batteries from a fast and cheap 3D printing process. “All-polymer batteries offer several advantages over conventional lithium-ion batteries,” says Mecerreyes, vice-director at Polymat – the Basque Centre for Macromolecular Design and Engineering, University of the Basque Country. “First, they don’t require toxic and scarce inorganic materials such as lithium, cobalt, nickel or manganese. Then, all-polymer batteries offer other advantages such as the use of renewable bio-based materials, flexibility, recyclability and the possibility of using additive manufacturing methods such as 3D printing for their fabrication. Our dream with iPES-3DBat was to develop materials that allow people to print their own battery at home.”

From biopolymers to low-energy applications

While battery cells traditionally have a planar structure, 3D printable inks would allow for the creation of different shapes. It would also provide higher power and energy density due to the increased surface area of electrodes. To create these inks, the iPES-3DBat project used novel redox polymers previously developed under iPES. These include biopolymers abundant in nature such as lignin, which also implies a much easier recycling process. Besides their optimisation for 3D printing, the biopolymers have three main things in common. They are environmentally safe, free of toxic chemicals and made of renewable resources. “The 3D printing part wasn’t easy. We had to print between three and five different layers (conducting layer, anode, cathode and electrolyte) and ensure that they all worked together smoothly,” Mecerreyes notes. The project successfully demonstrated several 3D polymeric batteries, although these cannot yet compete with lithium-ion batteries in high-energy applications such as electric vehicles or mobile phones. But they are still useful, as Mecerreyes points out: “We could foresee niche applications for thin or 3D batteries in (micro)electronics, health, the internet of things or toys, for instance.” The prototype batteries do quite a good job with tunable voltages between 0.5 and 1.5 V and energy/power density in the order of 80.6 Wh kg‒1 / 348 kW kg‒1, which may be enough for such applications. The batteries are quite robust and can live through more than 1 000 cycles. “With POLYKEY, we now intend to provide the market with polymers for batteries as well as sustainable polymer solutions for plastic recycling and bio-based industry. Since the end of the project, we have been working on scaling up our materials portfolio and looking for partners and investors interested in this technology,” Mecerreyes concludes.