A game changer in the photovoltaic industry

As photovoltaic technologies evolve, more sustainable solutions become available with the use of eco-friendly processed nanomaterials in the construction of nanocrystal solar cells. In particular, the metal halide perovskite nanocrystal offers promise for efficient photovoltaic and photoluminescent materials due to its excellent optoelectronic properties, such as a high photoluminescence quantum yield over 90 %. The EU-funded FASTEST project developed a method for the synthesis of phase-stable inorganic perovskite nanocrystals in a high-throughput yield based on room temperature processing in an ambient condition. This method comprises antisolvent engineering for nanocrystal reprecipitation. The fabrication of perovskite nanocrystals includes injecting perovskite precursor solution into the antisolvent mixture, purifying the nanocrystal solution with washing solvents, collecting nanocrystals by using a centrifuge, and forming a perovskite by using a layer-by-layer deposition technique. “This method aims at increasing the nanocrystal reaction yield of perovskite nanocrystals in the desirable perovskite phase. It holds promises for simple and reliable production of perovskite nanocrystals in ambient conditions without using vacuum and temperature control,” explains project coordinator Min Kim. “We envision that it will become applicable for other types of perovskite nanocrystals with other metal combinations (e.g. Ge, Sn, Bi, and Ag) for various optoelectronic applications, such as light-emitting diodes, photovoltaics, lasers and photon detection.”

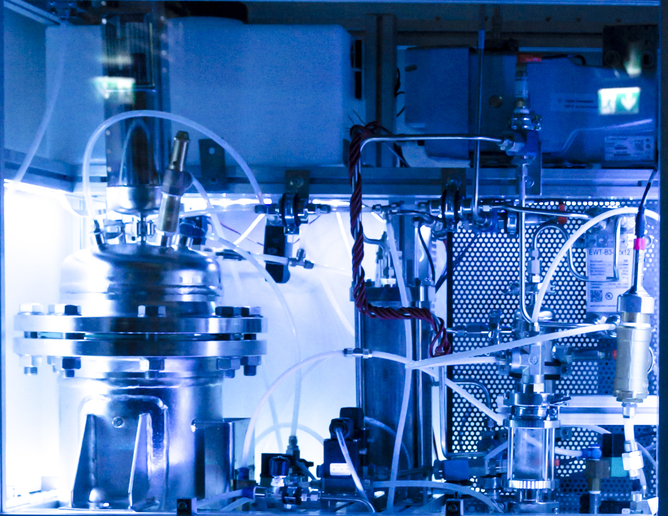

An insight into the lab

One of the main challenges of producing perovskite nanocrystals has been the high-throughput synthesis of monodispersed nanocrystal solutions with tailored optical properties and the conversion of these solutions to high-quality nanocrystal films. At the first stage of the project, while Kim was trying to deal with this matter, however, an additional issue occurred: the synthesised nanocrystal was not stable enough for device fabrication. This was due to the fact that the antisolvent in the crystallising solvent can also rip off some organic ligands which are supposed to be attached to the perovskite surface. “So, I added an auxiliary coordinating solvent in the crystallising solvent mixture, which was found to be more efficient in increasing production yield. The coordinating solvent is the key part of this work, but I cannot reveal the name of the chemical because the patent document is still under process,” confesses Kim.

Perovskite as a current and next-generation solution

The main advantage of the perovskite solar cell is its low-cost production compared to other types of photovoltaic technologies. “I hope the manufacturing of the perovskite nanocrystal solar cells will become more compatible with the large-area printing technique and will be easily scaled up in production, facilitating the commercialisation of the large-scale highly efficient solar cells,” says Kim. Nevertheless, his research in this field continues. He is looking for other perovskite materials that do not contain lead metal because it is a lead element, when it leaks, is considered a hazardous element to the human body as well as the environment. “To find a suitable combination of perovskite material, I will adopt a strategy of computer simulation and utilise the previously developed synthesis technique,” the fellow explains.