Automation drives cheaper fuel cell technology

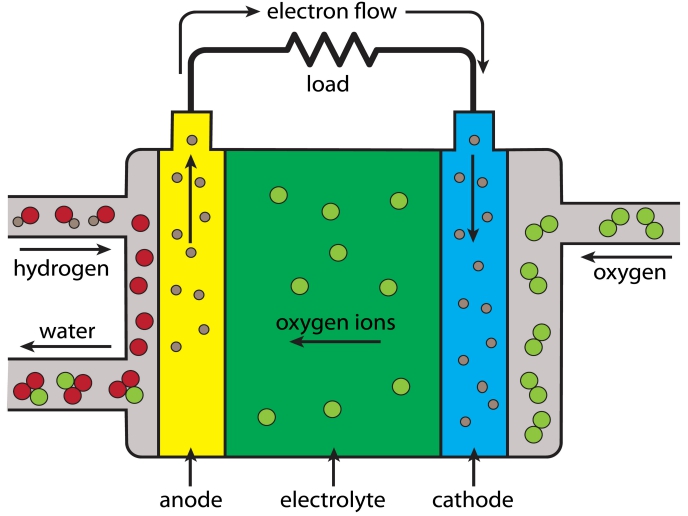

Solid oxide fuel cells(opens in new window) (SOFCs) are among the most promising renewable energy technologies for reducing carbon, sulfur and nitrogen oxide emissions. However, a single cell only produces some tens of watts of electricity. The solution is to arrange the cells in a stack to provide greater power – like batteries in a battery pack. In terms of mass manufacturing, fuel cell technology is at a relatively early stage. Only now have some fuel cell technologies matured to a high enough level for serious production to begin. But, despite significant progress over the last decade in SOFC technology, cost remains the greatest obstacle to wider acceptance. Current capital expenditure on state-of-the-art SOFC systems focuses on SOFC stack cost reduction and quality improvement. This would be achieved by replacing manual labour with automated procedures in all key parts of the stack manufacturing and quality assurance processes.

Quality inspection is the key

The EU-funded qSOFC(opens in new window) project addressed this challenge by developing automation and quality assurance for SOFC stack manufacturing. “This will lead to significantly cheaper SOFC stacks with higher quality, thus boosting market penetration of the technology,” says project coordinator Markus Rautanen. Researchers optimised key steps in cell manufacturing and quality assurance by developing and testing a high-speed cell-manufacturing process. “This included an automated 3D machine vision inspection system(opens in new window) (MVIS) to detect defects in cell manufacturing,” Rautanen explains. Project partners designed and built a novel MVIS capable of fully inspecting a fuel cell within 10 seconds, detecting defects as small as 10 μm in size. “We also developed the test matrix for the application of an advanced analysis tool known as Distribution of Relaxation Times(opens in new window) (DRT) for assessing and quantifying the performance of cells, stacks and stack components,” notes Rautanen.

A world leader

DRT is an analytical tool for interpreting data from electrochemical impedance spectroscopy and is capable of distinguishing and qualifying each electrochemical process. According to Rautanen: “DRT can examine the quality and homogeneity of a given cell batch and identify any anomalies or need for specific improvements faster and more extensively than traditional methods.” This allows cell manufacturers to conduct quality control of cell batches to evaluate the consistency of electrochemical response and produce a statistically relevant quality control dataset. The dataset is used for benchmarking the impact of modifications on the manufacturing process. These include changes in raw material source and typology and improvements in cell architecture, similar to those already well established in other fields that involve mass manufacturing. By developing manufacturing and quality assurance procedures suitable for mass production of stacks and stack components, such as individual fuel cells, qSOFC strengthened Europe’s position as a leader in fuel cell and hydrogen technologies. “These promise to provide a more sustainable future and new business opportunities for companies across the EU and increase the competitiveness of the European fuel cell industry, as well as benefiting society as a whole,” concludes Rautanen.