Novel scanner system monitors food processing for safety

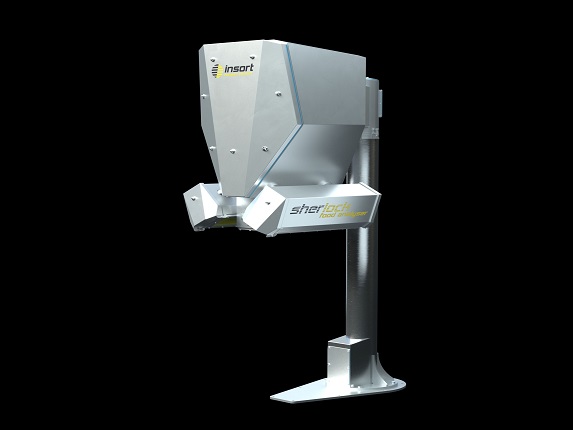

Nearly all foods distributed in packets go through a mechanised packing process. Although such product lines are carefully inspected, undesirable items and substances sometimes get through. This can include foreign materials, such as plastic, glass and stones, which could injure consumers. Spoiled food can poison consumers. Food companies have a strong incentive to avoid such consequences. However, inadequate current visual inspection methods make that difficult. These companies need an automated food-safety scanner for production lines. The EU-funded Food Monitor project developed such a scanner. It uses hyperspectral imaging to detect foreign objects and harmful substances, plus a high-resolution optical camera to detect anomalies. The prototype system called the Sherlock Food Analyzer(opens in new window) was first developed to Technology Readiness Level(opens in new window) 6 by the Austrian company Insort(opens in new window). The EU funding has allowed the company to upgrade all technologies to the final stage of full market readiness.

Automated hyperspectral imaging

The analyser is a high-speed camera system. It can be easily added to existing food-factory production lines, where it scans and analyses the contents in real time. Analysis is based on false-colour coding applied to the output of hyperspectral imaging and optical cameras. The colour coding is calibrated to laboratory results, plus can be used for qualitative (good/bad) and quantitative (percentage) judgements. The hyperspectral imager splits the near-infrared band into 240 spectral segments at each pixel. Each segment exhibits a pattern of dark and bright lines, which can be interpreted to indicate the presence of particular substances. So a hyperspectral scanner is a sophisticated chemical detector that, using reflected light alone, produces a complete chemical picture for every pixel of the image.

Monitoring food safety

“In terms of food safety, we are looking for foreign materials and harmful substances,” explains Anton Scheibelmasser, project coordinator. “Regarding food quality, we are looking for any kind of product defects, including mouldy or rotten food.” The system is effective for virtually any type of food transportable on a factory conveyor or shaker, except those having a thick peel or shell that near-infrared cannot penetrate. The scanner does not detect bacteria directly, which are too small for detection in the brief time available on a mechanised production line. However, the system can detect the chemical indicators of bacterial decomposition. “During the project, we made big improvements resulting from new state-of-the-art technology,” adds Scheibelmasser. “In terms of the hyperspectral imaging camera, we were able to detect target chemicals in dry matter measurement at less than 1 % concentration. We also increased the resolution of the optical camera so that it can scan areas smaller than 1 square millimetre.” All results were demonstrated on a conveyor moving at up to 2 m/s and proven during field testing at a customer facility. The team also added Industry 4.0(opens in new window) interface to the machines, making data handling and operation easier. The Sherlock Food Analyzer system is now available commercially. It allows rapid detection of harmful substances and objects in mechanised food production lines. This will improve consumer health and safety.