Lighter, cheaper, higher-density lithium batteries on the horizon

An EU initiative could lead to batteries that can store more energy per unit weight and volume, based on the long-lasting quest of using pure lithium metal in the battery anode. The design is part of the forward-looking concept for developing safe solid-state batteries, eliminating the need for a liquid electrolyte between the battery’s two electrodes.

Why promising alternatives to lithium-ion batteries matter

Lithium-ion batteries literally got portable electronics off the ground, but the list of practical applications extends beyond just running applications on a smartphone or a tablet. Electric vehicles, grid energy storage, power backup systems are just a few examples that are powered by this battery technology. This growing demand for lithium-ion batteries has brought global competition to the playground. But how is Europe faring in this competition? “Europe seems to have lost the battle of manufacturing conventional lithium-ion cells to Asian behemoths. We established the EU-funded IMAGE(opens in new window) project to bring back and broaden the technical know-how in the field so that the European battery industry gets a leg-up to the competition,” notes Kohs Wolfram, project coordinator and development engineer at AVL List GmbH(opens in new window). Bringing together industrial and academic partners, IMAGE worked to establish a well-documented roadmap for manufacturing cost-effective and competitive battery cells. The research was not limited necessarily to lithium-ion batteries as are but to more advanced and promising lithium alternatives.

Lithium-ion vs lithium-metal

The search for lithium-ion battery alternatives is relevant in applications where the technology has reached its limits. “This especially holds for electric mobility, which is largely driven by the demand for affordable lithium-ion batteries with a higher energy content,” remarks Wolfram. “Lithium-metal batteries are promising alternatives for electric vehicles, where large range and low weight and volume are big concerns.” A lithium-metal battery can outcompete conventional lithium-ion technology, storing about twice as much electricity per kilogramme. It does this by replacing the anode material (typically graphite) with a thin lithium sheet, which is lighter. Storing significantly more energy in less weight lengthens the electric vehicle range.

Improved electrolyte and cathode materials

Another element that could help unlock superior battery performance is the use of a new gel-polymer electrolyte, which has been intensively tested and improved in several loops. An electrolyte allows lithium ions to travel back and forth during the battery charging and discharging cycles, and a gel-polymer version could prove better than traditional liquid electrolytes. Project members also used a mix of nickel, cobalt and manganese for the cathode, which was optimised so that it could be used with aqueous binders instead of organic ones.

Laying the foundations for advanced lithium battery technologies

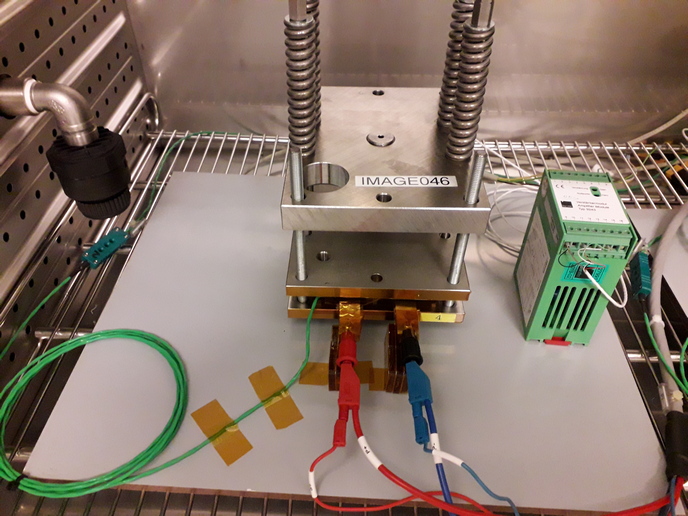

In the past, AVL List was involved in another project, testing various material combinations for the anode, cathode and electrolyte in its effort to cement a strong and competitive European battery industry. “In the framework of IMAGE, we experimented with new battery materials and built a new cell type. The materials used were cheaper and involved less energy-intensive processes during their production. Importantly, we dispensed with the need for organic solvents, opening a pathway to increased battery safety,” notes Wolfram. The process of synthesising the polymer-gel electrolyte is promising for engineering stable and conductive electrolyte interfaces. Furthermore, the addressed challenging design issues related to the mechanical integration and temperature control of the cells set a solid basis for follow-up projects. “Combining a thin electrode sheet with a gel-polymer electrolyte offers a cheap, scalable alternative to lithium-ion batteries, marking a step forward for solid-state batteries. Broadening our know-how and production capabilities regarding this type of batteries could help Europe compete against its giant Asian counterparts,” Wolfram concludes.