A pioneering solar reflector for concentrating solar applications

Solar energy will play an essential role in our ability to reduce emissions and combat climate change. Photovoltaics generate electricity directly via excitement of semiconductor materials. Concentrating solar technologies that concentrate the sun’s rays with reflectors (mirrors) generate heat that can be used directly for industrial processes (concentrating solar thermal) or be stored to generate electricity 24/7 (concentrating solar power). These technologies can also produce green hydrogen through thermocatalytic or photocatalytic processes. Flexible concentrating solar technologies are top contenders for large scale production plants, but commercial solar reflectors face challenges. The patented curved solar reflector ‘RST’ developed by Tewer Engineering(opens in new window), formerly Thermal Power Engineering, solves these problems and can be used in all three applications. The EU-funded AUTO-RST project supported outstanding technical advances and development of fast and cost-effective large scale production processes, paving the road to market.

Concentrating solar reflectors: challenges imposed by the materials and design

Most solar reflectors are made of a layer of glass (silver mirror) glued to a layer of steel, a configuration brittle in strong winds and sensitive to temperature changes. According to Marco Antonio Carrascosa Pérez, chief executive officer of Tewer Engineering and project coordinator, “due to the different thermal expansion coefficients of glass and steel, temperature changes can alter the radius of curvature and optical properties. Increasing heat waves or the so-called blocking effect, heating of the back steel layer by reflection off the silver mirrors behind them, are culprits, the latter of which can even melt the glue.”

RST: a pioneering curved reflector exceeds expectations

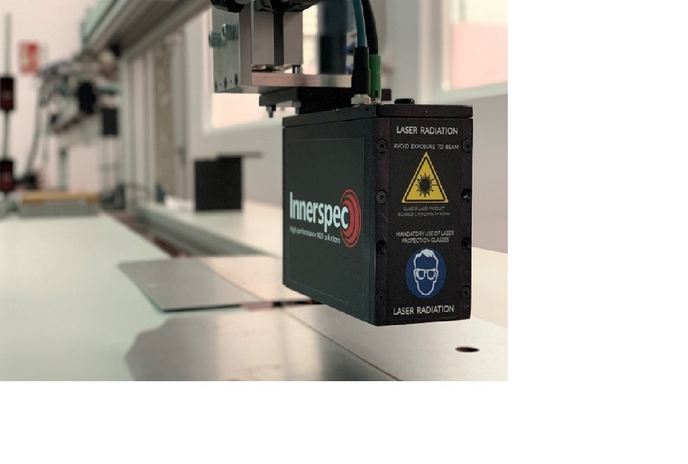

RST’s innovative sandwich configuration consists of front and back layers of glass, a silver and an aluminium mirror, respectively, separated by a layer of foam. The glass-to-glass configuration eliminates thermal expansion effects. The aluminium back mirror reflects the sun’s damaging UV rays, nearly eliminating blocking effects. The sandwich structure imparts enhanced stiffness, enabling the reflector to maintain optical quality under high loading conditions. Finally, “RST’s configuration allowed us to make the front mirror very thin, boosting reflectivity to 95.5 % for incredible system efficiency,” Carrascosa adds. Most commercial curved reflectors for heliostat(opens in new window) applications are 4 m2 with an optical quality of 1.2–1.4 milliradians (mrad) (a measure of how well the light beam can be focused – the smaller, the better). AUTO-RST set out to develop a large-scale production process for its RST that would achieve an optical quality of no more than 0.8 mrad and a cost/m2 on a par with that of competitors. “We have far exceeded our technical goals, producing reflectors 7.2 m2 in area – the largest in the world – with an optical quality of 0.4-0.6 mrad, a 50 % reduction in optical errors, an increase in reflectance under all environmental conditions and excellent corrosion resistance. All this was delivered with a production cycle time close to 20 min per reflector while meeting the target cost,” Carrascosa explains enthusiastically. Tewer’s automated assembly lines(opens in new window) are already cranking out the huge, high optical-quality reflectors at nearly double the pace of previous lines at two concentrating solar power plants. The team is also developing parabolic reflectors for both heat and hydrogen production. Concentrating solar technologies are heating up in a big way thanks to AUTO-RST’s outcomes.