Novel anti-icing layer boosts rotorcraft innovation

Icing conditions are a major aviation safety issue. All types of commercially operated aircraft – fixed-wing as well as rotorcraft – require ice protection systems in order to fly safely in all types of weather conditions. For so-called tilt rotor aircraft(opens in new window), in which rotors are tilted for different phases of flight, this presents some specific challenges. “Usually, aircraft can let ice build up a little on blades before the pilot switches on the heat,” explains NO-ICE-ROTOR(opens in new window) project coordinator Markus Villinger from Villinger GmbH(opens in new window) in Austria. “This however is not possible with tilted rotorcraft. When the blades in cruise flight are tilted vertically, the ice build-up is so significant that removing frozen material is like shooting rockets into the fuselage.”

Anti-icing systems for rotorcraft

Anti-icing systems are therefore required, to ensure that no ice develops. This has conventionally been achieved by installing metal wires that heat up electrically. However, because rotorcraft blades vibrate tremendously, this hot metal wire frequently breaks under the stress. Overheating of the rotor blade also represents a potential threat. “The reality is that most conventional ice protection systems don’t work very well for tilt rotorcraft,” says Villinger. To address this challenge, Villinger developed an ice protection system based on electrically heated coatings, which can be implemented into the blade structure. The coating can be applied in layers less than 0.2 mm thick, which means the weight of the aircraft is unaffected. The coating functions like an electrical resistance layer, providing uniform, full-surface heating.

Pioneering heating layer technology

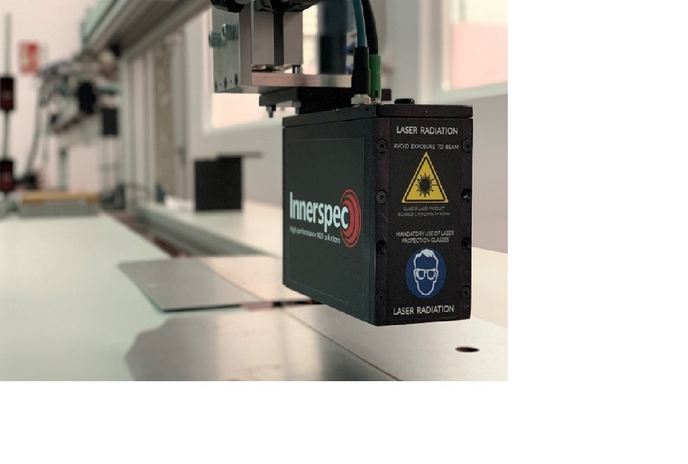

The aim of the EU-funded NO-ICE-ROTOR project was to implement and test this technology on the rotor blades of a next-generation advanced tilt rotorcraft. Such aircraft are still in the prototype phase, but will require effective ice protection in order to operate commercially. “We embedded our coating within the composite structures of the rotorcraft, to provide anti-icing capabilities under high loads and vibrations,” explains Villinger. “To do this, we calculated the power requirements of the heating layers, and defined the temperature range required to properly keep the rotor blades free of ice at all times.” Structural and environmental testing were conducted on representative test objects. The project team also designed and installed two de-icing systems capable of working independently of each other, to guarantee operations in case of a failure. Next, de-icing capabilities of two demonstrators were tested in the RTA Icing Wind Tunnel(opens in new window) in Vienna. Here, a number of tests were carried out under different conditions, and a great deal of data acquired.

Feasibility of novel ice protection

The collected data helped to underline the feasibility of the novel ice protection technology for tilt rotor aircrafts, even in the harshest of environments. “We see this project as the starting point for further development in ice protection for tilt rotor aircraft technologies,” remarks Villinger. “The coating can be integrated into composite materials without generating aerodynamic disadvantages. This means ensuring efficient air flight at high cruising speeds, with low fuel consumption and reduced noise.” Villinger and his team believe that the technology can service not only tilt rotorcraft, but also helicopters and unmanned aircraft. There is currently a great deal of excitement about the commercial potential of air taxis, which again will need effective de-icing technologies in order to be viable. “All this research is ongoing,” adds Villinger. “We are also beginning work on a novel type of ice detection system that will reliably activate ice protection automatically. This is something that also came out of this project.”