Catalytic process shows promise for getting propane from glycerol

Glycerol(opens in new window) is an organic compound, produced mainly from fats and oils, often used in health and beauty products. More recently, it has been touted as a feedstock for sustainable liquid and gaseous fuels. The Marie Skłodowska-Curie Actions(opens in new window) supported HYDROGAS project has explored glycerol as a feedstock to make hydrogen gas and biopropane. With no carbon emissions at the point of use, hydrogen is widely regarded as the most promising clean fuel of the future. While biopropane can replace the fossil-derived liquefied petroleum gases (‘camp gas’), but is also interesting for transport and off-grid heating applications. “Our approach was to use part of the glycerol itself, to produce the hydrogen gas required for biopropane production, avoiding the need for it to be added from expensive external sources,” explains principal investigator, Jude Onwudili from the Energy and Bioproducts Research Institute(opens in new window) at Aston University, United Kingdom, the project host. HYDROGAS’s first objective of developing a process to generate sufficient hydrogen to convert glycerol to biopropane was successfully met. While the second, obtaining high yields of biopropane, was not as successful, the team remain convinced of its feasibility.

An alternative source of hydrogen

Glycerol comprises three carbon atoms, each containing a hydroxyl group – one oxygen atom bonded to one hydrogen atom. As propane is a hydrocarbon molecule, made up of carbon and hydrogen atoms only, obtaining it from glycerol relies on the removal of its three oxygen atoms. This usually involves finding a catalyst that uses hydrogen gas to selectively remove the oxygen in glycerol as water, leaving propane molecules. However, hydrogen is expensive and mostly coming from fossil fuel, which is environmentally damaging. HYDROGAS’s innovation was to use some of the glycerol itself to produce the hydrogen needed to transform glycerol into biopropane.

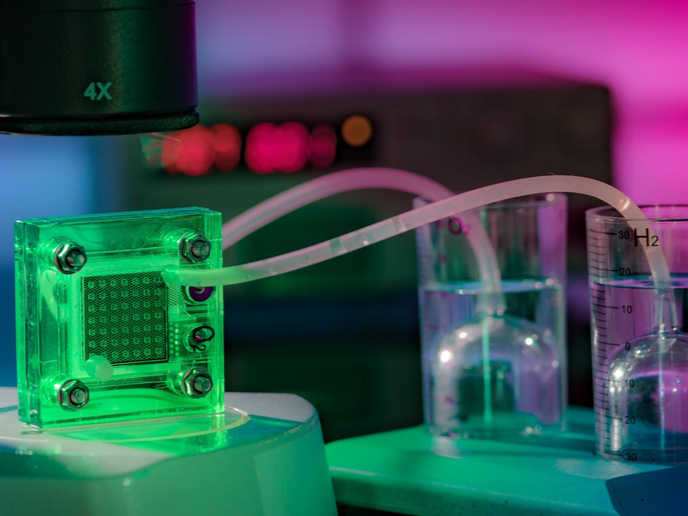

Two-stage catalytic process

As this requires multiple reactions using various catalysts, a two-stage process was developed. Various heterogeneous catalysts – those in a different state to the reactants; for example using a solid catalyst in a reaction that involves liquids – were tested for each step. To screen for the catalysts with the most stable activity in a batch reactor, these were tested at different temperatures, reaction times and glycerol concentrations. While expensive platinum-group metals(opens in new window) have typically been the main catalyst materials of interest, HYDROGAS afforded the chance to test cheap promising alternatives, based on alkali metals and first-row transition metals(opens in new window). “A central challenge of the aqueous phase of our reaction is that catalysts can deactivate quickly. A key result was finding a cheaper, highly active and stable catalyst, increasing the amount of biopropane we can get from glycerol at reduced cost,” says Carine Alves, research fellow from the Federal University of Bahia(opens in new window), Brazil. To avoid the need for costly and time-consuming pretreatments to remove impurities and ensure the stability of crude glycerol, the team used pure glycerol.

Benefiting the environment, jobs and energy security

The production of renewable hydrogen and low-carbon gaseous hydrocarbon fuels such as biopropane is a key part of the European Green Deal(opens in new window). For example, biopropane could become a fuel for more remote off-grid locations, joining the wider energy mix and creating new jobs. The team are currently optimising cheaper and more efficient catalysts to reduce the number of reactions needed to convert glycerol to biopropane. “We are also still working to obtain high biopropane yields from ‘crude glycerol’. Through HYDROGAS, we discovered that the second-stage reactions can work in non-hydrothermal conditions, so will explore this alternative route,” concludes Onwudili.