A new approach to making methanol: valorising marine litter

Plastics are essential to modern life, but managing plastic waste is a growing concern. The European Parliament estimates that between 4.8 and 12.7 million tonnes of plastic end up in the ocean every year. The CCLEANER project, supported by the Marie Skłodowska-Curie Actions programme(opens in new window), addressed this issue by exploring environmentally friendly ways to chemically recycle plastic waste.

Chemical recycling processes

The most well-known form of plastic recycling is mechanical. This involves sorting plastics by type and then reprocessing them into usable materials. Sorting is essential – as different plastics have different compositions that determine how they may best be used – but it is labour-intensive and costly. Mechanical recycling also uses excessive amounts of water to clean recycled plastics. The result is that mechanical recycling has high economic and environmental costs. Chemical recycling has the advantage of breaking down or rebuilding plastic molecules for reuse. Gasification, a pyrolysis process, utilises the carbon from marine plastics and converts them into valuable chemicals such as methanol. Prior to the gasification process, hydrothermal carbonisation(opens in new window) is utilised to generate hydrochar, a high-quality solid capable of boosting gasification. Since most plastics are initially made from fossil fuels, the recovered chemicals are suitable for many of the same applications, leading to improved valorisation of plastic waste. Methanol and hydrochar are the primary outcomes of chemically recycled plastic. In addition to plastic, methanol is a building block of many other materials. It is also used as a clean energy source for vehicles, fuel cells and stoves. Not only can hydrochar further boost the gasification process, it can also be used as an environmentally friendly replacement for coal and coke.

Seeking net-zero solutions

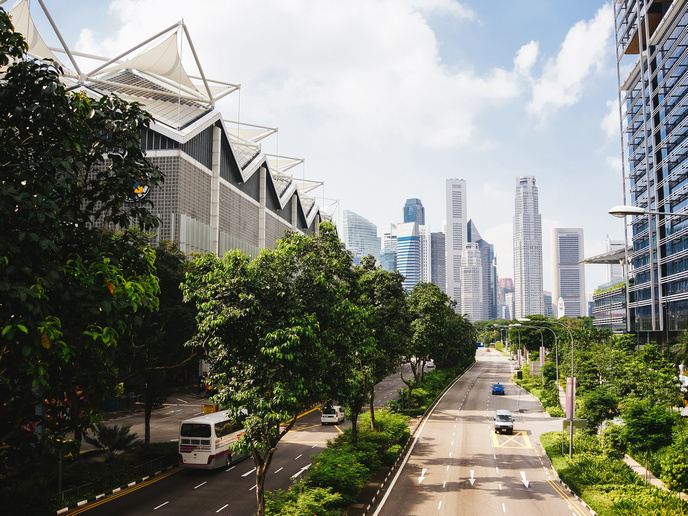

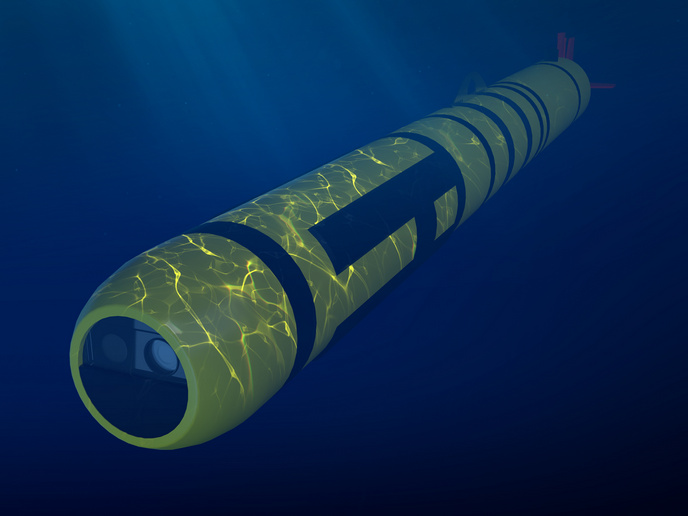

Such outcomes are exciting and essential to transitioning to a circular economy, but there is a catch – the energy needed to achieve pyrolysis often produces greenhouse gases. An important aim of the project is reducing the environmental impact of the chemical recycling process. According to project fellow Yi Cheng: “In terms of the total balance, a commercialised method of production requires a carbon source (waste plastics), a hydrogen source (water), and energy (renewable energy).” CCLEANER employed machine learning algorithms to explore many aspects of the operation. Researchers compared process models of onshore and shipboard plants, and AI was used to analyse the plastic litter(opens in new window) being processed. Cheng says: “The project provides a feasible approach to address floating marine plastic waste. We employed a machine learning method to tackle the unstable feedstock, which is a barrier to upcycling the widely various plastic particles.” Through the use of seawater as the reaction medium and employing renewable energy sources such as wind, wave and solar, CCLEANER has advanced a groundbreaking approach to the chemical recycling of plastics. The comprehensive life cycle assessments and techno-economic analyses conducted over the course of the project have led to insightful policy recommendations. Green methanol produced from waste plastic salvaged from the seas is within reach. Envision a ship or man-made island where plastic is gathered, energy is harnessed and chemical recycling yields high value products in return. With continued investment in a net-zero emission future, the project’s innovations in hydrothermal carbonisation technologies will yield cleaner oceans and economic and environmental sustainability, making that vision a reality.