How one EU project rewrote the rules for hydrogen electrolysis

Producing hydrogen through water electrolysis could revolutionise how renewable energy is stored and transported. Current proton exchange membrane electrolysis cells (PEMECs), which split water into hydrogen and oxygen, rely heavily on expensive materials and face issues with long-term performance. The EU-funded Thin-CATALYzER project(opens in new window) has developed an innovative catalyst layer architecture that combines carbon nanofibres, ultra-thin ceramic layers, and catalytic nanoparticles. This new design improves efficiency and reduces reliance on critical materials.

New catalyst architecture enhances performance

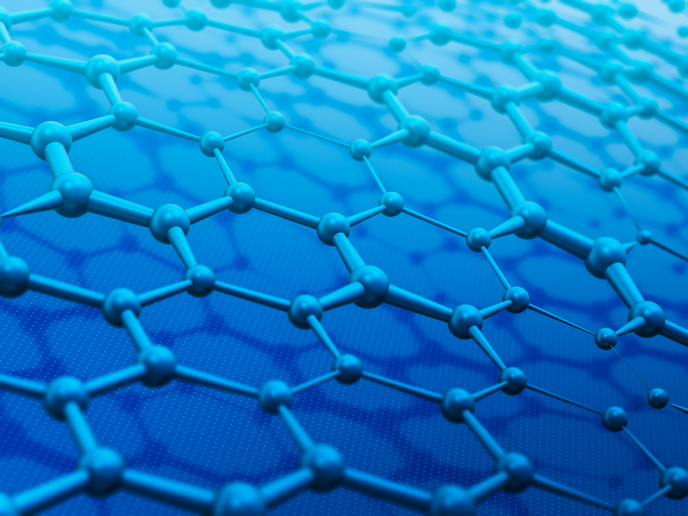

Thin-CATALYzER developed a core-shell catalyst layer made from carbon nanofibres coated with an ultra-thin ceramic layer of titanium oxynitride (TiON). On top, a fine dispersion of iridium nanoparticles enhances catalytic performance. "One of the most challenging aspects in the development of low-temperature electrodes operating in aqueous electrolytes is the relatively high level of technological maturity," explains project coordinator Federico Baiutti. "With Thin-CATALYzER, we explored the potential of combining thin-film fabrication methods with traditional chemical synthesis, aiming to provide a different technological perspective and open up new pathways for further progress in the field." The ceramic coating ensures electrical conductivity and protection against corrosion, while electrospinning(opens in new window) (a scalable technique suitable for industrial applications) produces high-quality carbon fibre supports rapidly and efficiently.

Tackling durability and material efficiency

Although reducing the amount of critical raw materials, such as iridium, is vital, this also presents challenges in balancing material efficiency with long-term catalytic performance. Nanostructured catalysts work better because they have more surface area, but they can break down or clump together when exposed to tough electrochemical conditions. Baiutti highlights that ongoing optimisation is crucial: "Balancing material efficiency with long-term catalytic performance remains a core challenge in the field. Achieving this balance requires ongoing optimisation of synthesis methods, support materials, and protective strategies." To enhance stability, the project explored the incorporation of dopants to prevent support oxidation and employed smart design strategies to ensure good catalyst performance under real operating conditions.

From laboratory breakthrough to industrial relevance

During the project, the team engaged with industrial partners to evaluate the commercial viability of their innovations. This revealed the importance of scalability and long-term reliability, by emphasising the significant gap between laboratory achievements and industrial requirements. "For an innovation to have a real impact, one must ensure an easy and scalable fabrication route, as well as high long-term performance and reliability," notes Baiutti. "Strengthening the connections between the scientific and industrial worlds would be extremely beneficial to align needs and efforts." The versatility of the Thin-CATALYzER design opens doors beyond electrolysis, potentially benefiting other low-temperature electrochemical devices, such as polymeric fuel cells and batteries. By adjusting material combinations, this technology could significantly advance the development of cleaner energy storage and conversion systems. Through this innovative catalyst design, Thin-CATALYzER has set the stage for more sustainable and efficient hydrogen production technologies, supporting Europe’s transition towards a greener economy.