Making the most of diesel engine catalysts

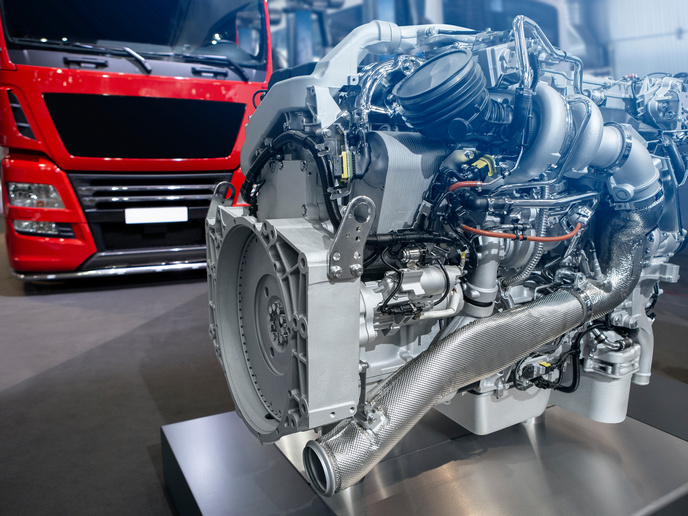

Freight transport is highly reliant on diesel engines. Fuel combustion causes diesel engines to oxidise some of the nitrogen in the air, leading to the release of nitrogen oxides. These compounds contribute to smog, negatively affecting air quality and public health. Diesel engines are equipped with catalysts to reduce such noxious compounds, but current catalysts degrade over time. The CHASS(opens in new window) project, supported by the Marie Skłodowska-Curie Actions programme(opens in new window), studied the causes of catalytic deactivation at the molecular level.

Understanding Cu-zeolites

Zeolites are naturally occurring minerals with a microporous crystalline structure. Their structural and chemical properties make them suitable for use as catalysts – they can increase the rate of a chemical reaction without undergoing permanent chemical change. In addition to naturally occurring zeolites, there are many synthetic examples, including copper (Cu)-containing Cu-zeolites(opens in new window) that are the industry standard for use in diesel engines. Cu-zeolites, particularly Cu-exchanged chabazite (Cu-CHA) zeolites targeted by the project, are able to reduce the nitrogen oxides in diesel engine exhaust gases, but two factors cause the catalyst to degrade over time. When diesel exhaust systems become too hot, particularly above the 150-500 °C range where they perform best, Cu-zeolites can break down. These catalysts are also particularly susceptible to even small amounts of sulfur dioxide (SO2), often formed during the combustion of diesel fuel.

Complementary approaches to understanding catalytic deactivation

CHASS brought together four PhD students, each with a distinct approach to understanding catalytic behaviour at the molecular level. Quantum mechanical calculations allowed for modelling based on density functional theory(opens in new window) and was paralleled by reactor flow experiments for sulfur poisoning. Project coordinator Gloria Berlier shares: “Quantum mechanical calculations were also used to describe at the atomic level the hydrothermal ageing of the catalyst, build a microkinetic model for dealumination(opens in new window) and aided the interpretation of experimentally studied effects of water on the reaction.” CHASS developed models using other approaches as well. In-situ and operando results using spectroscopic characterisation(opens in new window) were used to develop a model of sulfur deactivation, and the composition of materials and experimental data informed models of hydrothermal ageing of catalysts.

Atomic-level insights

Project results have advanced scientific understanding of how and why diesel engine catalysts deactivate. Catalysts are dynamic, which presents a challenge when trying to understand the paths of atomic reorganisation induced by a reaction. By computing the distribution and diffusion of Cu ions(opens in new window) in the zeolite and describing the movements of aluminium atoms in the catalyst, CHASS has delivered unique insight into reaction paths that impact Cu-CHA material. “We have identified the Cu sites more sensitive to sulfur poisoning and proposed a reaction mechanism compatible with the experimental results. We have shown that the poisoning effect of sulfur, in the form of SO2, is highly sensitive to the composition and pretreatment of the catalyst,” Berlier explains. Europe is planning to phase out fossil fuel-based vehicles after 2035, and diesel engines will need to be replaced with a green alternative, such as hydrogen combustion engines. The work of the early-stage researchers in the CHASS project has prepared the way for cutting-edge advances in developing the new catalysts needed for low-carbon future technologies.