Producing aviation fuels from the ground up

Aviation relies heavily on energy-dense fuels, making it the second-largest energy consumer in transport after road travel. Despite decades of technological advancements to improve energy efficiency, the sector still depends on fossil fuels, contributing significantly to the transport sector’s 13 % greenhouse gas emissions.

A new way to make jet fuel

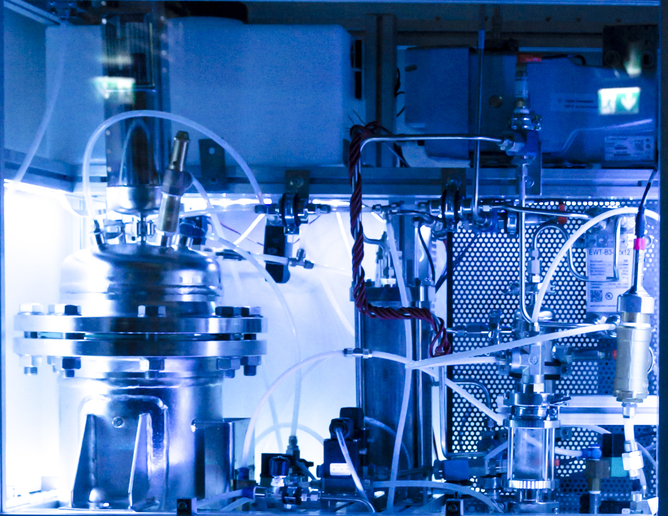

To reduce aviation’s reliance on fossil fuels, the EU-funded 4AirCRAFT(opens in new window) project explored innovative ways to produce jet fuel directly from CO2 and hydrogen (H2). The team developed a technology that converts CO2 into long-chain hydrocarbons (≥C8), which are used as jet fuel precursors. “We converted CO2 into carbon monoxide (CO) and hydrogen (H2) at room temperature, then transformed hexanol (a type of alcohol) into a hexene fraction under mild conditions (140-160 °C), followed by their conversion into long-chain hydrocarbons,” explains project coordinator Vanesa Gil. 4AirCRAFT’s concept is based on a single cascade reactor consisting of three interconnected modules. “We focused on optimising CO2 selectivity and electrochemical conversion into useful products (electrochemical reactor module) and on alcohol dehydration into hexenes and then long-chain hydrocarbons (by means of a biomimetic chemocatalytic reactor module),” adds Gil. The overall approach relies on producing alcohols from syngas (a mix of CO and H2) using a microbial module as an intermediate step. The CO2 electroreduction module uses a zero-gap membrane electrode assembly design, achieving 48-96 % selectivity for CO and 52-96 % for CO + H2 at room temperature. The biomimetic chemocatalytic module converts alcohols like 1-hexanol into long-chain hydrocarbons and jet fuel precursors. Using 3D-printed, clay-inspired catalysts, it dehydrates 1-hexanol into hexenes with up to 96 % alkene yield and converts alkenes into hydrocarbons and esters with a 95 % conversion rate.

Better catalysts for cleaner fuels

The project used advanced electro- and chemocatalysts optimising their environments to make the process more energy-efficient. Zinc (Zn)-based catalysts achieved 90 % selectivity for CO production and 94 % for a CO and H2 mix. In the second step, the challenging step of hexanol dehydration into the desired hexenes reached over 70 % yields at the lowest temperatures ever reported for this reaction. The most effective catalysts included compounds like hafnium triflate, copper triflate, triflic acid and clay-based materials, all used in low catalytic amounts (2-10 mol %).

Enzymes as biocatalysts

Furthermore, researchers explored the use of biocatalysts for alcohol dehydration, improving how these catalysts are stabilised as well as making the Fischer-Tropsch synthesis (a chemical process converting CO and H2 into liquid hydrocarbons) more efficient under mild conditions. One focus in biocatalysis was on exploring linalool dehydratase isomerase (LinD) – a natural enzyme that dehydrates alcohols. Tested in different forms, including whole cells, purified enzyme, cell pellets and crude extracts, it effectively dehydrated some primary alcohols like geraniol but struggled with others. However, it showed strong potential for converting allylic alcohols into high-value products.

Boosting enzyme performance with metal-organic frameworks

To further improve enzyme performance, the team used metal-organic frameworks (MOFs) – structures that can safely encapsulate enzymes. ”While this reduced activity, it established a foundation for creating stable enzyme-MOF hybrids, opening new possibilities for advanced catalyst engineering,” emphasises Gil.

Overcoming limitations

Conventional fuel production methods relying on fossil sources often lack efficiency, selectivity and high conversion rates. 4AirCRAFT demonstrated efficient, flexible and scalable technology to convert recycled CO2 into sustainable liquid fuels, focusing on designing catalytic materials to overcome energy barriers in key reaction steps.