New static 3D X-ray scans improve container inspections at ports

Every day, thousands of containers roll through European ports. Customs teams must quickly determine which loads look normal and which warrant closer inspection. For years that decision has relied on 2D X-ray images that can be hard to interpret when cargo is tightly packed, sealed or deliberately cluttered. The EU-funded MULTISCAN 3D project(opens in new window) aimed to improve what customs inspectors could see inside freight containers without slowing trade. Between 2021 and 2025, the project developed and validated key components of a static 3D X-ray tomography system for large cargo. After laboratory work, the technology was tested at an industrial site operated by Smiths Detection in Vitry-sur-Seine near Paris, using conventional accelerators under realistic inspection conditions.

Building a static 3D scanner for real containers

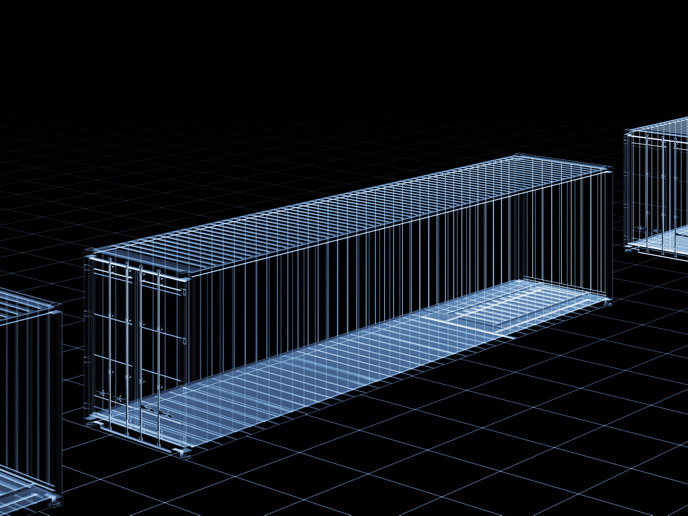

Traditional cargo radiography typically delivers a single main view and limited information on material properties, creating blind spots for threats that lack a clear outline. As the project coordinator Christine Mer puts it: “Current 2D X-ray imaging systems are limited in their ability to detect poorly defined threats, such as drugs.” MULTISCAN 3D’s approach is to move from planar images to 3D slices by combining new detector technology, 3D reconstruction algorithms with a limited number of projections and a novel X-ray source concept based on laser-plasma acceleration. Instead of a slow-rotating gantry, the system concept uses a static ring around the cargo, with the load translating through it while multiple views are acquired.

Fast 3D inspection designed for high-throughput ports

High-throughput sites need technology that fits around existing traffic flows. In MULTISCAN 3D’s concept, the ring includes detector arrays and a set of interaction chambers where X-rays are produced. The laser beam can be distributed to different chambers pulse by pulse, so that the data for a tomographic slice are collected in one-tenth of a second. The system concept targets rapid processing, with a container scan completed in 3-4 minutes, supporting throughputs of 15-20 40-foot containers per hour. Alongside imaging, the consortium has been developing beam monitoring and dosimetry while exploring complementary techniques to help identify chemical substances and special nuclear materials in a second line of inspection. This architecture supports fast scans while remaining modular and relocatable for different deployment settings, from busy ports to land borders and temporary checkpoints. It also lays the groundwork for automating classification because 3D information can combine shape with density patterns. In Mer’s words, “This advanced technology will enable non-intrusive verification of declared goods, thereby accelerating customs clearance for routine commercial shipments.”

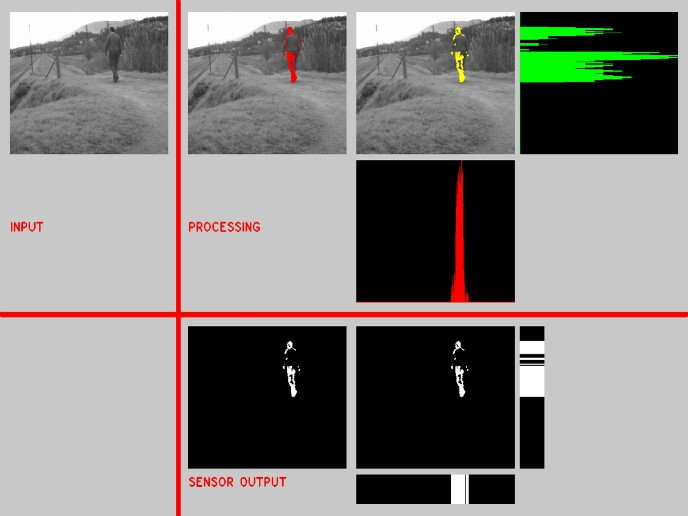

Real-scale tests deliver first 3D images

In Vitry, the team tested a 5-metre prototype of the detector technology on a real container prepared with scenarios developed by Dutch and Belgian customs, including drug simulants hidden in challenging locations such as tyres. “The first 3D images have been obtained on a container loaded with relevant materials provided by Dutch and Belgian customs, including drug simulants,” Mer notes. The reconstructions used 44 different views to help locate suspicious materials more precisely than a single 2D projection, even when other goods occluded items. With 3D resolution in the 2–3 cm range and complementary high-resolution 2D images (below 2 mm), the concept demonstrates how static tomography could make inspections more accurate and less disruptive, with potential applications in border security and future cargo screening needs such as supporting recycling and waste-sorting operations.