A new tool boosts fuel cell market competitiveness

Fuel cells, which generate electricity through electrochemical processes, provide a green alternative to fossil fuel-based approaches. While significant advancements have been made in fuel cell technology in recent years, this promising alternative to electricity production has not yet taken off because it still fails to match the affordability, availability and reliability of conventional solutions. The EU-funded RUBY(opens in new window) project has made strides in changing that. A dedicated toolbox featuring a monitoring, diagnostic, prognostic, and control (MDPC) tool employs a Real Time Optimisation (RTO) algorithm for control and electrochemical impedance spectroscopy (EIS)(opens in new window), a widely-recognised method for studying phenomena occurring within fuel cell stacks, to improve the efficiency of fuel cells and lowered their cost.

Targeting stationary fuel cells

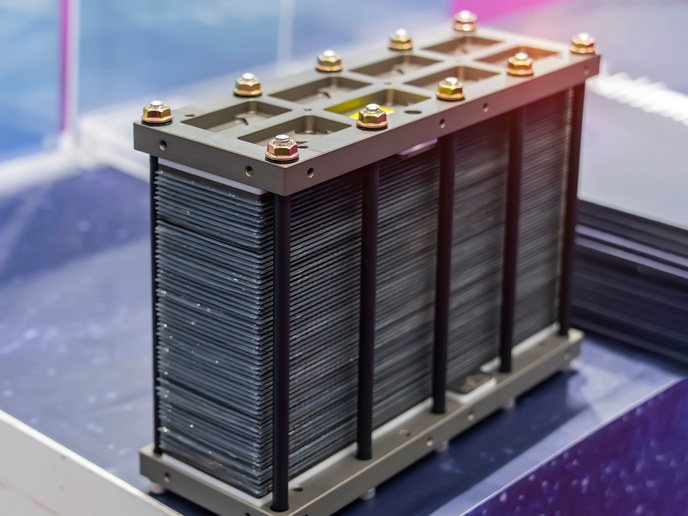

Fuel cells (FCs), which are far more environmentally friendly than energy systems running on fossil fuels, are used in many circumstances, including transportation, stationary power generation and mobile applications. When pure hydrogen is used as fuel, fuel cell stacks, which typically include hundreds of cells, produce only water and heat as by-products of generated electricity. Two of the most technologically mature types of FCs are solid oxide fuel cells (SOFCs), which require high temperatures to perform, and proton-exchange membrane fuel cells (PEMFCs), which operate at lower temperatures. RUBY developed tools to assess both types of FCs under stationary conditions.

MDPC, EIS and the RUBY solution

EIS is based on the concept of impedance(opens in new window), a complex measure of a material’s response to the flow of alternating current. In EIS, a current stimulus is applied at various frequencies to the FC stack and the resulting voltage responses are measured. These measurements constitute the spectrum of impedance data to which the MDPC tool is applied. While EIS is the industry standard for analysing the electrical characteristics of fuel cells, RUBY’s innovations will make this approach much more viable. “EIS is commonly performed in laboratory environments using high-cost instruments, but RUBY demonstrated the possibility of implementing EIS on FC systems operating in the field. The proposed approach unlocks the possibility of providing an effective, low-cost solution for commercial FC systems,” shares project coordinator Cesare Pianese.

Experimental campaigns involving PEMFCs and SOFCs

RUBY tested the MDPC tool effectiveness on 110 electrochemical spectra from PEMFC systems and 259 spectra from SOFC systems. The results were impressive. According to Pianese: “The EIS-based diagnostic algorithm detected 100 % of faulty conditions and isolated 85 % of the faults occurring in PEMFC, whereas for SOFC, 100 % of faulty states were detected and 70 % of the faults were isolated.” Furthermore, the RTO control algorithm developed by the project led to a 5 % increase in the efficiency of the SOFC-based combined heat and power system. “It is worth mentioning that this improvement has been achieved in a fraction of the time and at a fraction of the cost that would be required to deliver a comparable performance gain through a major innovation in materials or design,” Pianese notes. The RUBY solution is low-cost as well as versatile. The MDPC tool, based on both EIS diagnostics and RTO control, can be applied to any electrochemical device. Many of the tools developed by the project are publicly available through the project website. RUBY’s advances have contributed to bring environmentally friendly fuel cells much closer to widespread market uptake.