Novel properties of novel materials

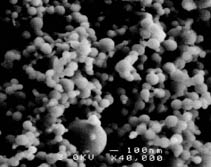

Single crystal materials exhibit order throughout the bulk of the material and are quite difficult to prepare, whereas polycrystalline materials are more widely encountered. These are materials made up of a huge number of very small single crystals, known as grains. When the grain size is of the order of a few nanometers (1nm=10-9m) we have nanophase materials. A nanophase metal is five times harder than the normal polycrystalline metal. When grains impinge on each other we have the creation of grain boundaries. It is at the grain boundaries that scientists speculate that a novel disordered state might exist that will explain the observed behaviour of these materials. Amorphous metals represent another category of novel materials. These materials, unlike the conventional metals, possess a non-crystalline, without any order microstructure, such that is usually found in glasses. They are also known as metallic glass alloys and due to their peculiar microstructure they exhibit unique physical properties. They can combine strength and hardness with flexibility and toughness. The current project has launched an extensive experimental and theoretical investigation on the mechanical properties of nanophase metals, thin films and amorphous metal alloys. Plastic instabilities were investigated experimentally by using metallography, electron microscopy, X-ray analysis, high-speed cinematography and mechanical testing. With the use of classical and gradient theories of elasticity, the elastic properties of defects were calculated. A technique based on virtual surface dislocations led to exact elastic solutions defects in these novel materials. The important boundary value problem for a screw dislocation near the junction of three different phases characterised by different elastic moduli has also been solved. The knowledge produced will gradually lead into better fabrication techniques and optimisation of strength properties of these materials. Their application ranges from aerospace technology to anti-theft tags and electrical distribution transformers.