Zinc for storing the sun's energy

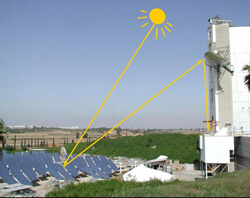

The reduction of zinc oxide (ZnO) with carbonaceous material using concentrated solar irradiation as energy source is an innovative concept for the storage of energy in zinc (Zn) as a "solar fuel". The energy content of zinc can subsequently be recovered as electricity in Zn-air fuel cells or zinc can be used to produce high purity hydrogen by reacting with water vapour. In both processes ZnO is formed, which can be reprocessed in the solar reactor to produce metallic zinc once again, with drastically reduced CO2-emissions compared to conventional fossil fuel-based Zn-production. Aiming at experimentally evaluating the solar carbothermic ZnO-reduction process at a pilot scale, the SOLZINC project supported by the European Commission designed and manufactured an innovative two-cavity solar reactor. A mixture of zinc oxide combined with coal, coke or carbon biomass is placed into the well-insulated lower cavity, the reactor chamber. An array of heliostats reflects solar light to a hyperbolic mirror, which in turn reflects the light rays vertically down through a secondary concentrator in the solar reactor located on the ground. The solar irradiation heats the upper cavity through a quartz window, which then indirectly heats the lower cavity. At temperatures above 1000 °C the ZnO and carbon react mainly to gaseous zinc and carbon oxides. The gaseous products are removed via an off-gas pipe which is connected to a cooler for condensing zinc and creating a fine zinc powder that can be safely handled and transported. The carbon monoxide can be used for energy. After extensive trials with different lab-scale prototypes, a pilot scale chemical reactor was integrated into the solar-power facility of the Weizmann Institute of Science in Israel with an output that reaches 1 MW. The first trials were successful in using 30 per cent of the available solar energy for the chemical reaction and producing 45 kg of zinc per hour in line with projected goals. On a full scale industrial facility, much larger amounts could be extracted using a similar process. The process runs with fossil coals as well as with biomass e.g. in the form of charcoal. If the later is used the entire process can be CO2 neutral.