Cheaper and more efficient solar cells

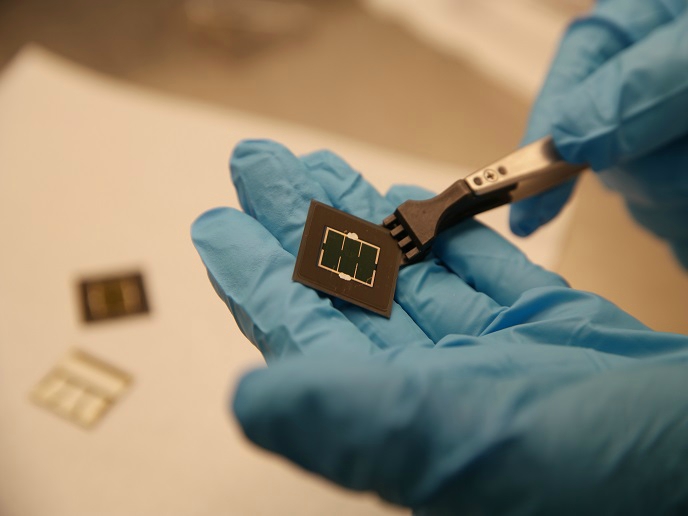

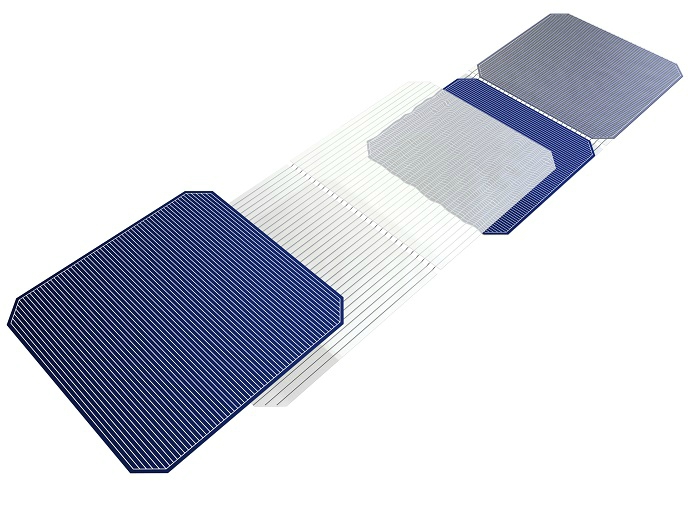

Crystalline silicon (c-Si) wafer-based technology has genuine potential for significantly reducing the cost of solar cells. However, a number of critical issues must first be addressed. They include a reduction in the amount of silicon material consumed (for example using thinner wafers) and an increase in solar cell efficiency. One of the most promising avenues of research is silicon heterojunction cells, which depends on a low temperature growth of ultra-thin silicon layers on both sides of a crystalline silicon wafer substrate. The role of the EU-funded HETSI project is to design, develop and test more efficient heterojunction solar cells that are compatible with high-throughput mass production. The cell design is based on an emitter and back surface field produced by a low temperature growth of ultra-thin layers of silicon. Modelling new concepts is crucial to effective design and development. Simulation results obtained with two different softwares have shown excellent correlation. The software has now been upgraded to take into account additional factors. Project partners have also developed wet-chemical processes and dry cleaning processes that have resulted in higher cell efficiencies. Different deposition methods for doped metal oxides used in photovoltaics, called transparent conductive oxides (TCO) and include indium tin oxide (ITO), have been compared. The sensitivity of ITO in damp heat tests on solar cells shows that aluminium foil is required on the back to prevent the penetration of water. Metallisation conducted with low-temperature screen printed pastes from a number of different suppliers reveals that resistivity is too high for a single print process and a multiple print process should be investigated. Metallisation was finally applied to actual large area solar cells. The HETSI project shows that a new approach can be applied to the development of a competitive solar cell using c-Si wafer-based technology to reduce costs and increase efficiency. The results will also help boost the European solar cell industry and create more jobs in the renewable energy sector of the new green economy.