Auto-assessment of vehicle composites

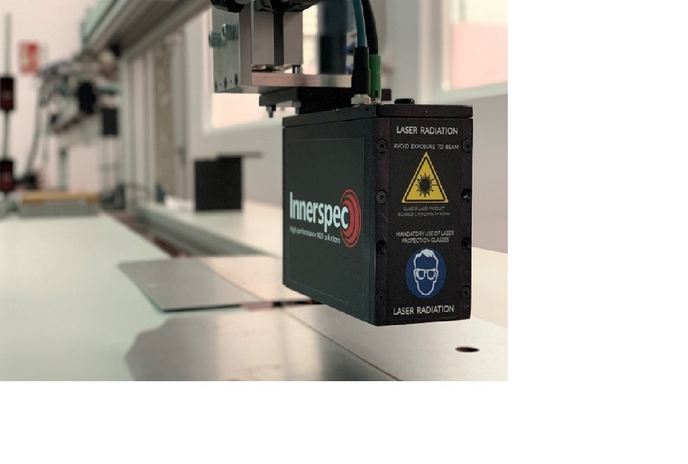

Composite materials, such as plastics reinforced with glass or carbon fibres, are increasingly used in the automotive and rail industries. Damage to and repair of such materials may cause significant service disruption, yet the development of non-destructive testing techniques has been relatively slow. The EU-funded COMPAIR(opens in new window) (Continuous health monitoring and non-destructive assessment of composites and composite repairs on surface transport applications) project devised a new system for non-destructive monitoring. The system assesses the state of composite materials, and repairs, in surface transportation applications. Such applications include road and rail vehicles as well as marine vessels. Project outcomes included development of a mobile robotic scanner, which quickly inspects on-site composite panels. The mobile scanner works by capturing images of panels in stationary trains or trucks. The scanner head inspects glass fibre-reinforced plastics using near-infrared combined with a Basler camera. Testing of carbon fibre-reinforced plastics utilises transient thermography techniques and a forward-looking infrared camera. Thus, the scanner head determines the composition of tested materials. The scanner interacts with project-developed control software to ensure smooth and reliable operation. Called Compair, the software includes criteria for determining the fitness of scanned materials. Additionally, Compair constantly maintains the head at right angles to the scanned surface, even on curved panels. The software also stitches together the separate images created by the cameras, to produce a single image for the operator, revealing any defects. Researchers developed a monitoring technique able to inspect composite structures in real time. The method combines acoustic emission and long-range ultrasonic guided wave techniques. The combination of techniques permits detection and localisation of subtle variations in the composite materials, resulting from excessive loading or bending. Pattern recognition software pinpoints the location of a defect, defined according to acceptance criteria thresholds. Field trials demonstrated the effectiveness of the project’s system. Other project activities included extensive market analysis, which yielded a market strategy. The team also created an operator’s manual, incorporating best practice guidelines for use. COMPAIR’s system will mean in-place monitoring of composite materials used in various types of vehicles, giving real-time results. Such monitoring means early detection of faults and minimal disruption to transportation services.