Special materials drive Li-ion battery improvements

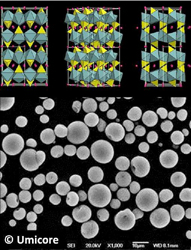

The 'Power oriented low cost and safe materials for Li-ion batteries' (Pomerol) project aimed to achieve a breakthrough in materials needed to develop high-power, low-cost and safe lithium-ion batteries. The materials and batteries are intended for use in fuel-cell hybrid and conventional hybrid drive-train automotive applications. The EU-funded project worked to provide the materials and means that meet the challenge of reducing the cost of high-power lithium-ion batteries to EUR 25/kW. This is a critical aspect for achieving widespread development of technology needed to drive fuel-cell hybrids. The Pomerol consortium further aimed to develop a long-life and intrinsically safe electrochemical high-power battery as well as to propose innovative solutions based on the development of speciality materials. In the initial selection of the first generation of materials, graphite and other materials were selected and up-scaled. SLS30 graphite was chosen for the negative electrode as it meets all requirements and offers the best compromise between power and calendar life. For the positive electrode, team members chose low-moisture–content LiFePO4 material. The choice of a particular standard electrolyte was based on the negative impacts on power and inadequate safety improvements characterising the use of ionic liquid-based electrolytes. Pomerol's researchers also identified ionic liquids and designed the first electrolyte compositions. A total of 28 final cells were produced, but could not be delivered due to high self-discharge. A proposal was made to perform deep post-mortem analyses of these cells and deliver one module with remaining cells from the second set of validators for a final abuse test. These included the same design as that for final cells. Resources used were adequate and in good agreement with original project planning in order to achieve the goals set. The Pomerol project reached all milestones and work on further developments and study of a second generation of materials to improve calendar life at elevated temperatures continues.