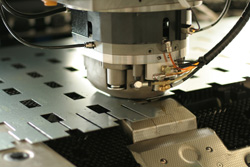

Coating cutting tools for better machining operations

Applying selected physical vapour deposition (PVD) nano-structured coatings can enhance cutting tools and benefit machining with a technology already successfully applied to the machining of other materials such as steel alloys. Such coatings can reduce friction and the risk of overheating and perhaps even do away with the use of lubricants. This promises to achieve faster machining speeds, a delay in the appearance of local wear defects and longer tool life. The EU-funded 'Innovative PVD nano-coatings on tools for machining titanium and nickel alloys' (Matina) project focused on longer cutting-tool life, faster machining and reducing/eliminating the use of lubricants and coolants for more economic production of nickel (Ni) and titanium (Ti) parts. New coatings were designed with a specific doping element, with project partners also having worked to develop other nano-structured coatings. Different deposition parameters were analysed to determine influences of target doping power, process temperature and nitrogen partial pressure. Coating synthesis was optimised and coatings were selected for application on certain tools used to perform machining tests. A PVD coating applied by magnetron sputtering on cutting tools resulted in up to 30 % increased productivity when machining Ti alloys. In the future, machining workshops will be able to use machining procedures with the chosen coatings and tools to machine components such as those used in aircrafts. Matina's outcomes are of special interest to the aeronautical, biomedical, energy and manufacturing sectors.