Novel shape memory tools for stone processing

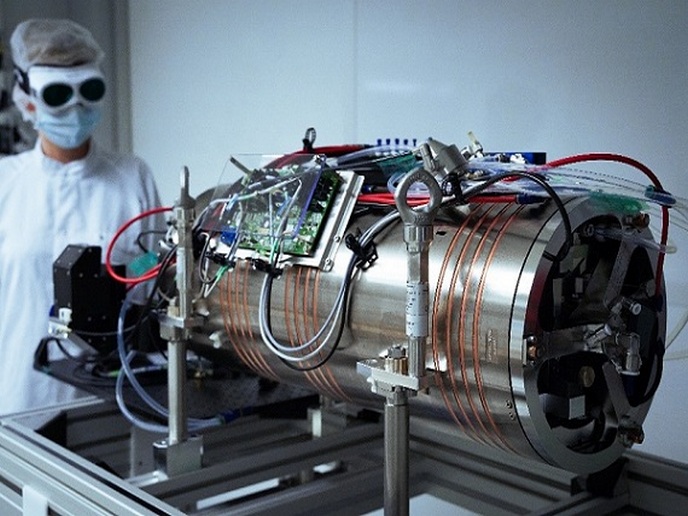

Recently, the European stone processing machinery and tools sector has been feeling the pinch due to competition from Far Eastern and southern American suppliers. The many reasons for this include low productivity, high energy consumption and critical safety for workers. There are also issues regarding high wastage and environmental friendliness as stone is a non-renewable resource. The need for technological advances to solve these problems has so far been addressed with the use of knowledge-based multifunctional materials in stone tools and equipment. The most promising research avenue is the application of SMA technology. An SMA or smart alloy is an alloy that 'remembers' its original cold-forged shape and returns to the pre-deformed shape on heating. The EU-funded 'Eco-efficient and high productive stone processing by multifunctional materials' (PRO-STONE) project aimed to build on work already done by consortium members on these novel materials. In particular, PRO-STONE addressed the low level of reliability of macro-level SMAs by comparison with micro-scale SMA devices so far developed in the medical sector. A primary objective was to correlate the characteristics of at least 10 ornamental stone types with equipment parameters such as forces generated, energy consumption and tool wear ratio. Stone types analysed included granite, gabbro, quartzite, marble and limestone. For four SMA families including nickel-titanium-copper and the ferromagnetic nickel-manganese-gallium alloys, data was collected on fatigue behaviour (strength and cycles). To be able to guarantee repeatable and reliable performance of multifunctional SMA-based components, at least 10 different geometries and dimensions of tools were tested in relation to multiaxial monotonic or cyclic loading and large forces as experienced in stone extraction, for example. Project scientists characterised and developed models for the generated forces and displacements for the selected SMA component geometries and the arrays of complex elementary geometries that are used as actuators. To validate the design of the design support system, prototypes of demonstrators were tested using various applications. To fully utilise the research results from the PRO-STONE project, the team have set up an e-training section in the knowledge web platform aimed at stimulating creation of new SMA applications in small and medium-sized enterprises (SMEs). Importantly, the module incorporates an interactive element to identify user knowledge needs. Deliverables of the PRO-STONE project will contribute to solving the industry's specific needs and improve its technological status. Increased awareness by SMEs of new SMA technologies for processing stone stands to transform this traditional, regionalised industry into a modern and competitive sector.