Innovative design of wind turbine blades using carbon nanotube-based composites (WINDBLADE)

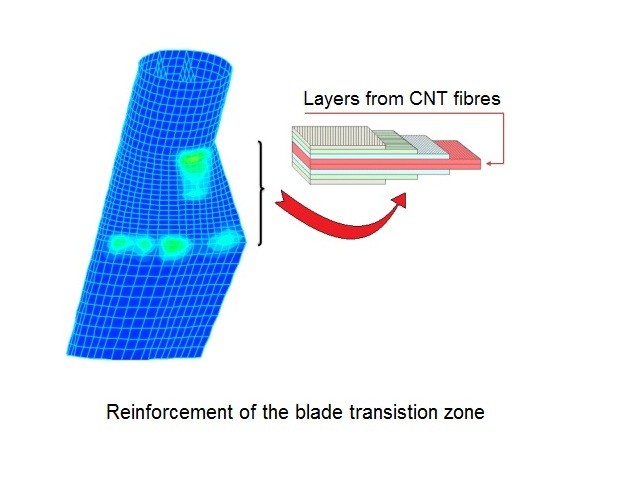

In response to global warming issues and energy access challenges, wind power is seen as a key source of clean energy with no emission of greenhouse gases or air pollution. In this context, the technological interest to develop large and more powerful machines is becoming nowadays a major concern for the wind-turbine industry worldwide. Thereby, obtaining a high electrical power output depends mainly on the swept area of the rotating blades, that is, the larger the size of the blades the more energy is captured. However, such blades are exposed during their service life to severe conditions of loading which may generate negative effects on their structural behaviour and this may lead to structural damage. To achieve a new design strategy of the actual blades, generally made of glass and/or carbon fibre-reinforced composites, carbon nanotube (CNT) materials arranged in the form of continuous fibres and embedded in a thermoplastic matrix are intended to replace the classical fibres. The main choice of these nano-materials is related to the ultra-high-performance indices in terms of specific stiffness, specific strength and other extraordinary physico-chemical properties such as thermal and electrical conductivity, which are not achievable with classical fibres. For instance, the strength of these fibres can be several times higher than standard carbon fibres and weigh much less for an equivalent cross-section. These competitive advantages make CNT fibres a very attractive candidate for reinforcing wind turbine blades, thus enabling the production of ultra-mega sources of clean energy. The above figure illustrates a case study of a stress concentration within the blade transition zone, where another layer of unidirectional continuous fibres made of single-walled carbon nanotubes replaces the over-stressed layer that was initially made of classical fibres. With this alternative, the analysis deals with the case of hybrid composite blade consisting of two types of fibre reinforcements. In addition to this feature, the layer made of CNT fibres can play, thanks to its excellent electrical and thermal properties, the role of active sensor providing information on the behaviour of the structural blade when subjected to high static and dynamic loads, including hygrothermal expansions. It is in the context of global efforts to fight against climate change for which the WINDBLADE project has been developed to improve the design process of future wind turbine blades. This will providentially offer great potential for the development of clean energy and will guarantee a new security of energy supply. However, besides these advantages, the requirements of ecodesign for energy related products has to be integrated in all design stages for sustainable and eco-friendly production of high-performance composite wind turbine blades, allowing them to operate safely under harsh conditions with high degree of reliability. Furthermore, the project aims to support the EU’s triple energy target (3x20 EU’s energy objectives) that should be achieved by 2020, namely: · 20% reduction in greenhouse gas emissions; · 20% rise in the share of renewable energies; and · 20% reduction in energy consumption.