Polymer film for quiet, low-energy buildings

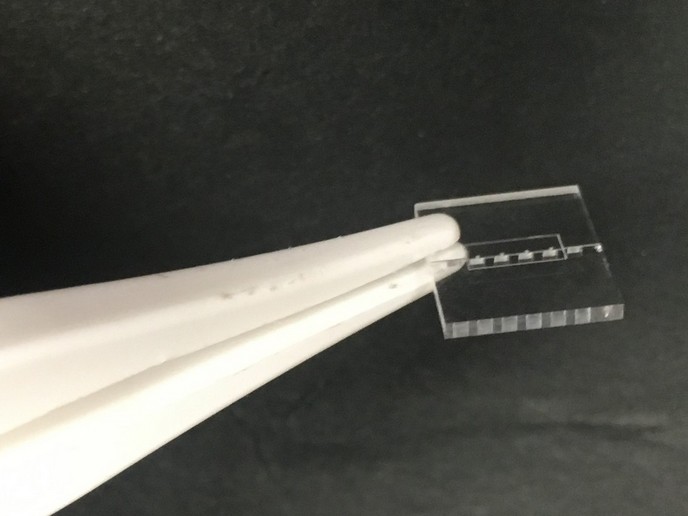

Conventional low-cost sound-absorption materials, such as mineral wool, also insulate walls and ceilings and are therefore unsuitable for use in passive heating or cooling. An alternative solution for countering noise in buildings is micro-perforated panels, but they are too expensive for widespread use. However, a cost-effective sound-absorbing polymer film was developed under the auspices of the ECHO2ECO (A novel sound absorption technology to enable energy efficient construction techniques and promote the health and wellbeing of occupants) project. The film can solve problems associated with room acoustics and does not pose a barrier to the use of thermal mass in a building. The ECHO2ECO initiative developed a new type of sound absorber for public and non-residential buildings. The low-cost, high-performance sound absorber comprises a 200-micron-thick polymer film with an array of laser-cut micro slits a mere 100 microns wide. The slits facilitate passive heating and cooling in buildings, and the material is translucent so that natural light can pass through it. Researchers investigated different polymer materials and conducted screening tests on a number of different polymers with regard to their physical and mechanical properties. Tests were also carried out to ensure that the material could be laser processed with no loss to the product's performance. Scientists studied different aspects of the laser machining process, including laser wavelength and power, material absorption, speed, and quality of cut or polymer formulation. Key acoustic dampening properties of the film were identified, modelled and tested. The different acoustic properties were successfully determined. Researchers also developed a number of experimental protocols for characterising prototype materials and carried out work to improve the performance of the film structure. The end result of the ECHO2ECO project was an extremely thin sound-absorbing film that can be applied to ceilings, walls and windows, and which can also improve energy use in buildings. The EU Energy Performance of Buildings Directive (EPBD) requires governments, designers and clients to take steps to reduce energy use. This includes the application of passive heating and cooling techniques such as thermal mass. Moreover, the EPBD states that attaining good energy performance must not compromise the quality of the indoor environment. The polymer fill developed by ECHO2ECO will allow buildings to comply with these regulations by providing a low-cost solution for sound absorption in public and commercial buildings. It will also meet EU legislation demanding improved energy efficiency in buildings while protecting the health of its occupants.